Contact

E-mail us

ASTM B619 Hastelloy Tubes Supplier in Mumbai India. ASTM B619, B622 Seamless, Welded, ERW Tubes ASTM B619 Hastelloy ERW Tubing Supplier in Mumbai India.

Table of Content

Hastelloy tubes are high-performance alloy tubes built to handle extreme heat and corrosive environments. Made from a blend of nickel, chromium, molybdenum, and other metals, they offer strong resistance to oxidation and chemical attack. They are a popular choice in heat exchangers, pressure vessels, and process equipment where reliability under stress is critical. Available in grades like as Hastelloy C22, C276, and B2, these tubes can be seamless or welded, depending on the application. Preston Pipes & Alloys is a leading Hastelloy tube supplier, offering products that meet global standards for mechanical strength, durability, and precision manufacturing. To meet the needs of various industries, their product line includes a wide range of diameters and wall thicknesses.

Hastelloy tubing is regarded for its durability and performance in harsh environments. It is resistant to pitting, crevice corrosion and stress corrosion cracking even in severe chemical conditions. Industries such as chemical processing, marine engineering, electricity generation and pollution control rely on it to keep operations running smoothly. Hastelloy seamless tube designs work well in high-pressure and high-temperature applications, whereas Hastelloy welded tube options are recommended for large-diameter and custom-length projects. Its versatility makes it an ideal solution for both small-scale applications and heavy-duty industrial systems.

These tubes are available in a wide range of specifications to match varied applications. They are made to ASTM A387 / ASME SA387 specifications. Thickness extends from 1 mm to 300 mm, and widths from 1000 mm to 4050 mm. Lengths vary from 2000 mm to 15000 mm to suit different installation needs. Surfaces may be finished as 2B, 2D, BA, No.1, No.4, No.8, 8K, mirror, or checkered. Customers can choose between hot rolled (HR) and cold rolled (CR) finishes based on the project requirements. The combination of dimensional variety and multiple finishing options ensures a perfect fit for both standard and custom builds.

Each batch of Hastelloy tubes is subjected to stringent quality control procedures to assure performance, and safety. Dimensional accuracy, hydrostatic pressure and non-destructive examination are done of the tests used to find defects. Only material that passes mechanical and chemical property tests moves forward for dispatch. Packaging follows international export standards with proper end caps, waterproof wrapping, and secure wooden boxes or pallets to prevent damage in transit. For a reliable supply of high-quality Hastelloy tubing that performs in the toughest conditions, choose us as your trusted supplier.

| Specifications | ASTM B619, B622 / ASME SB619, B622 |

| Standard | ASTM, ASME and API |

| Dimensions | 6 mm OD x 0.7 mm to 50.8 mm OD x 3 mm thk. |

| Schedule | SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Type | Seamless / ERW / Welded / Fabricated / LSAW Tubes |

| Form | Round, Square, Rectangular, Hydraulic Etc |

| Length | Single Random, Double Random & Cut Length. |

| End | Plain End, Beveled End, Treaded |

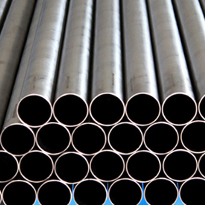

Hastelloy Seamless Tube

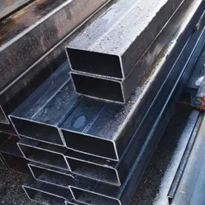

Hastelloy Welded Tube

Hastelloy ERW Tube

Hastelloy EFW Tube

Hastelloy Round Tube

Hastelloy Square Tube

Hastelloy Rectangular Tube

Hastelloy Polished Tube

Contact Preston Pipes and Alloys for best offer & competitive

quotation of Hastelloy Tubes

| Grade | Ni | C | Mo | Mn | Si | Fe | P | S | Co | Cr |

| Hastelloy C22 | Balance | 0.010 max | 12.5 – 14.5 | 0.50 max | 0.08 max | 2 – 6 | 0.02 max | 0.02 max | 2.5 max | 20 – 22.5 |

| Hastelloy C276 | Balance | 0.010 max | 15.00 – 17.00 | 1.00 max | 0.08 max | 4.00 – 7.00 | 0.04 max | 0.03 max | 2.5 max | 14.50 – 16.50 |

| Hastelloy B2 | Balance | 0.02 max | 26 – 30 | 1.00 max | 0.1 max | 2.0 max | 0.04 max | 0.03 max | 1.0 max | 1.0 max |

| Hastelloy B3 | 65.0 min | 0.01 max | 28.5 | 3.0 max | 0.10 max | 15 | 0.2 max | 0.03 max | 0.20 max | 1.5 max |

| Hastelloy X | Balance | 0.05 – 0.15 | 8.00 – 10.00 | 1.0 max | 1.00 max | 17.00 – 20.00 | 0.04 max | 0.03 max | 0.50 – 2.50 | 20.50 – 23.00 |

| Grade | Density | Melting Point | Yield Strength (0.2% Offset) | Tensile Strength | Elongation |

| Hastelloy C22 | 8.69 g/cm3 | 1399 °C (2550 °F) | Psi – 45000 , MPa – 310 | Psi – 1,00,000 , MPa – 690 | 45 % |

| Hastelloy C276 | 8.89 g/cm3 | 1370 °C (2500 °F) | Psi – 52,000 , MPa – 355 | Psi – 1,15,000 , MPa – 790 | 40 % |

| Hastelloy B2 | 9.2 g/cm3 | 1370 °C (2500 °F) | Psi – 51,000 , MPa – 350 | Psi – 1,10,000 , MPa – 760 | 40 % |

| Hastelloy X | 8.22 g/cm³ | 1355 °C | 240 MPa | 655 MPa | 35 % |

| STANDARD | UNS | WERKSTOFF NR. | AFNOR | EN | JIS | BS | GOST |

| Hastelloy C22 | N06022 | 2.4602 | – | NiCr21Mo14W | NW 6022 | – | – |

| Hastelloy C276 | N10276 | 2.4819 | – | NiMo16Cr15W | NW 0276 | – | ХН65МВУ |

| Hastelloy B2 | N10665 | 2.4617 | – | – | – | – | – |

| Hastelloy B3 | N10675 | 2.4600 | – | – | – | – | – |

| Hastelloy X | N06002 | 2.4665 | – | – | – | – | – |