Contact

E-mail us

ASTM A789 S31803, S32205, S32750, S32760 Duplex, ASTM A789 2507, 2205 Seamless, Welded, ERW Tubes SAF 2205, SAF 2507 Tubing Supplier in Mumbai India.

Table of Content

Preston Pipes & Alloys is a trusted name in supplying high-quality piping products across industries. We offer duplex and super duplex steel tubes built for strength and reliability. Duplex steel tubes are made from a mix of austenitic and ferritic stainless steel structures. This blend gives them better resistance to stress corrosion and high strength. Super duplex stainless steel tube has the same dual structure but with more alloying elements. It offers higher corrosion resistance, especially in harsh environments like offshore or chemical processing. Duplex tube material usually includes chromium, nickel, molybdenum, and nitrogen. Super duplex includes those plus higher levels of these elements to handle aggressive conditions. As leading super duplex tube suppliers, we meet demanding applications worldwide.

Duplex stainless steel tubes are used in heat exchangers, oil and gas pipelines and structural systems. These tubes work well where high strength and good weldability are needed. On the other hand, super duplex tube has better pitting and crevice corrosion resistance. It's used in subsea equipment, chemical plants, and marine structures where higher performance is a must. Both types ensure long life and low maintenance in various applications.

We supply ASTM A789 Super Duplex Tubing in a range of sizes and specifications. Super duplex tube outer diameter ranges from 6.00 mm OD up to 250 mm OD, with sizes available up to 12” NB. Duplex stainless steel seamless tube size range is 4 mm to 219 mm with thickness between 0.5 mm to 20 mm. Length options include single, double random, and custom cut. These tubes are manufactured through cold drawing and seamless extrusion methods to ensure tight dimensional control and strong surface finish.

Our tubes go through quality checks to meet international standards. Every Super Duplex Steel Tube is tested with visual inspection, chemical and mechanical tests, and third-party checks. We also offer Material Test Certificates (MTC) as per EN 10204/3.1B, along with 100% radiography reports and raw material certificates. As trusted duplex tube suppliers, we pack every order carefully to prevent damage. Our tubes are available in custom surface finish, end finish, dimensions, shapes, sizes, length, and toughness. Get reliable tubes built to perform in every condition.

| Specifications | ASTM A789 / ASME SA A789 |

| Standard | ASTM, ASME and API |

| Seamless Tubes Range | 1 / 2" NB - 8" NB |

| Welded Tubes Range | 6" NB - 24" NB |

| Outside Diameter | 6.00 mm OD up to 250 mm OD, Sizes up to 12” NB |

| Length | Single Random, Double Random & Required Length |

| Thickness | 0.3mm – 50 mm |

| Schedule | SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH120, SCH140, SCH160, XXS |

| Type | Seamless, EFW, Fabricated |

| Form | Round Tubes, Square Tubes, Rectangular Tube |

| End | Plain End, Beveled End, Treaded |

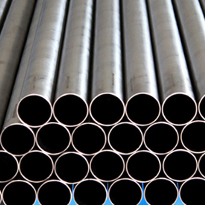

Duplex / Super Duplex Steel Seamless Tube

Duplex / Super Duplex Steel Welded Tube

Duplex / Super Duplex Steel ERW Tube

Duplex / Super Duplex Steel EFW Tube

Duplex / Super Duplex Steel Round Tube

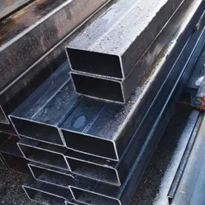

Duplex / Super Duplex Steel Square Tube

Duplex / Super Duplex Steel Rectangular Tube

Duplex / Super Duplex Steel Polished Tube

Contact Preston Pipes and Alloys for best offer & competitive

quotation of Duplex / Super Duplex Steel Tubes

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| S31803 | 0.030 max | 2.00 max | 1.00 max | 0.030 max | 0.020 max | 22.0 – 23.0 | 3.0 – 3.5 | 4.50 – 6.50 | 0.14 – 0.20 | 63.72 min |

| S32205 | 0.030 max | 2.00 max | 1.00 max | 0.030 max | 0.020 max | 21.0 – 23.0 | 2.50 – 3.50 | 4.50 – 6.50 | 0.8 – 0.20 | 63.54 min |

| S32750 | 0.030 max | 1.20 max | 0.80 max | 0.035 max | 0.020 max | 24.00 – 26.00 | 3.00 – 5.00 | 6.00 – 8.00 | 0.24 – 0.32 | 58.095 min |

| S32760 | 0.05 max | 1.00 max | 1.00 max | 0.030 max | 0.010 max | 24.00 – 26.00 | 3.00 – 4.00 | 6.00 – 8.00 | 0.20 – 0.30 | 57.61 min |

| Grades | Density (g/cm³) | Density (lb/in³) | Melting Point (°C) | Melting Point (°F) |

| S31803 / S32205 | 7.805 | 0.285 | 1420 – 1465 | 2588 – 2669 |

| S32750 / S32760 | 7.8 | 0.281 | 1350 | 2460 |

| STANDARD | WERKSTOFF NR. | UNS |

| Duplex 2205 | 1.4462 | S31803 / S32205 |

| Super Duplex 2507 | 1.4410 | S32750 / S32760 |