Contact

E-mail us

ASTM B162 Nickel Alloy 200 Sheet, Alloy UNS N02200 Coil, Supplier of Nickel 200 Plate in Mumbai, India

Table of Content

Preston Alloys is a leading supplier of nickel alloy 200 sheets, plates and coils known for their purity, and strength. Nickel 200 is suitable for harsh conditions due to its exceptional resistance to heat and corrosion. The substance is utilized in heat exchangers, tanks, and piping systems in the chemical processing industry, among other industries. It also finds applications in electronics and electrical uses like battery components, wire and anodes. In aerospace and defense, nickel 200 supports jet engines, and structural elements. The offshore, and marine industry depends on its corrosion resistance in rough, salty environments. As a trusted nickel 200 sheet supplier, Preston Pipes & Alloys offers a wide range of forms to meet varied industrial needs.

Nickel 200 mainly consists of nickel with minor amounts of elements like carbon, manganese, silicon, sulfur, copper, and iron. This composition gives it a strong corrosion resistance and high durability. The alloy has a density close to 8.9 grams per cubic centimeter and melts at around 1446 degrees Celsius. It delivers high tensile and yield strength along with good elongation, which allows it to be shaped and formed without cracking. These mechanical properties make nickel 200 sheets and plates reliable for demanding uses where both strength and flexibility matter.

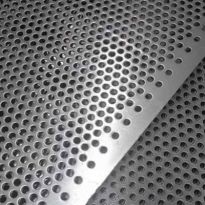

Nickel 200 sheets, plates, and coils come in a broad range of sizes and finishes. Lengths range from 2000 mm to 6000 mm, while widths range from 1000 mm to 3500 mm. Thickness varies from thick plates up to 120 mm to thin foils of 0.3 mm. The material is available in coils, foils, rolls, plain sheets, flats, strips, chequered plates and blanks in circles. Surface finishes include hot rolled plates and cold rolled sheets. Custom sizes are available upon request, providing flexibility for any project. Coils made of nickel 200 are easy to store and use effectively in production processes. Nickel 200 coils allow for easy storage, and efficient use in manufacturing processes.

Strict testing is performed on each batch to ensure that its mechanical and chemical features meet industry standards. The packaging is modified to protect the contents during transit, and the surface quality is meticulously examined. Depending on the needs of the customer, products may be shipped in steel strip bundles, plastic bags, or wooden boxes. This ensures the material arrives intact and ready for immediate use. Depend on reliable nickel 200 plate suppliers to deliver consistent quality and service.

Pure Nickel Alloy 200 Plate Stock, Ni 200 Shim Sheet, ASME SB162 Nickel 200 Strip, WNR 2.4066 Foil, 200 Nickel Perforated Sheet

| Type | Specifications |

| Alloy 200 Plate Specification | ASTM B162 UNS N02200, ASME SB162, MSRR, AMS, BS |

| Nickel 200 Plate Sizes | 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm |

| Ni 200 Plate Thickness | 0.1mm to 100 mm Thk |

| Nickel 200 Plate Width | 10-2500mm |

| Ni 200 Plate Length | 2m, 2.44m, 3m, or as required |

| Nickel 200 Sheet ASTM | ASTM B162 |

| Ni 200 Sheet AMS | AMS 5553 |

| Nickel 200 Plate Finish | Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) |

| Ni 200 Sheet Hardness | Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc. |

| Nickel 200 Plate Stock in form of | Ni 200 Plate, Sheet, Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Strip, Flats, Clad Plate, Rolling Sheet, Flat Sheet, Rolling Plate, Flat Shim, Blank (Circle), hot rolled, cold rolled, annealed, soft annealed, descaled, sheared, tread plate, Checker Plate |

| Material | JIS: N0, N2, N1, NW2200, NW2201, NW4400,

NW5500, NW6002, etc DIN:H-Ni99.96, H-Ni99.95, H-Ni99.92, H-Ni99.90, H-Ni99.5, H-Ni99, etc |

| Nickel 200 Plate ASTM Standard | ASTM A162, GB/T2054, DIN177502002, etc |

| Nickel 200 profiling |

To provide a full profiling service we use numerous profiling methods including:

|

| Specialized in |

|

| Size (Inch) | Size (mm) |

| 3/16" | 4.8 mm |

| 1/4" | 6.3 mm |

| 3/8" | 9.5 mm |

| 1/2" | 12.7 mm |

| 5/8" | 15.9 mm |

| 3/4" | 19 mm |

| 1" | 25.4 mm |

| Dimension (mm) | Kg P/M2 |

| 2.0 * 1219 * 3048 | 18 |

| 1.6 * 1200 * 3048 | 14.4 |

| 3 * 1200 * 3000 | 27 |

| 0.7 * 1219 * 3048 | 6.3 |

| 3.18 * VARIOUS ANN | 28 |

| 0.5 * 1000 * 2000 | 4.5 |

| 0.9 * 1219 * 3048 | 8.1 |

| 1.2 * 1219 * 3048 | 10.8 |

Nickel 200 Sheet Metal

ASTM B160 Type Nickel 200 Perforated Sheet

Nickel 200 Chequered Plate

Nickel 200 Plain Sheet

Nickel 200 Cold Rolled Sheet

UNS N02200 Hot Rolled Plate

Nickel 200 Strip

Nickel 200 Coil

Nickel 200 Foil

Nickel 200 Shim Sheet

Nickel 200 Shim Stock

Get in touch with us for the best deal on Nickel Alloy 200 Sheet, Plate and Coil

| Procedure | Electrode / Filler Metal |

| Gas-Metal-Arc Welding | Nickel Filler Metal 61 |

| Shielded Metal-Arc Welding | Nickel Welding Electrode 141 |

| Gas Tungsten-Arc | Nickel Filler Metal 61 |

| Element | Nickel 200 | Nickel 201 |

| Nickel (plus Cobalt) | 99.0 minimum | 99.0 minimum |

| Copper | 0.25 | 0.25 |

| Iron | 0.40 | 0.40 |

| Manganese | 0.35 | 0.35 |

| Carbon | 0.15 | 0.02 |

| Silicon | 0.35 | 0.35 |

| Sulfur | 0.01 | 0.01 |

Nickel 200, Typical Values at 70°F (21°C), Plate—Hot Rolled, Annealed

|

0.2% Offset |

Strength |

in 2 inches |

|

||||

| ksi | MPa | ksi | MPa | % |

(3000-kg) |

B |

|

| Nickel 200 | 15–40 | 105–275 | 55–80 | 380–550 | 60–40 | 90–140 | 45–73 |

| Property | Value |

| Density | 0.321 lbs/in³ 8.89 g/cm³ |

| Specific Heat | 0.109 BTU/lb-°F (32–212°F) 456 J/kg-°K (0–100°C) |

| Modulus of Elasticity 78°F (26°C) | 29.7 x 10³ ksi 205 GPa (20°C) |

| Thermal Conductivity 212°F (100°C) | 463 BTU-in/ft²-h-°F 66.5 W/m-°C |

| Melting Range | 2615 – 2635°F 1435 – 1446°C |

| Electrical Resistivity | 58 Ohm-circ mil/ft at 70°F 0.096 µΩ/m at 20°C |

| Temperature Range °F | °C | 10⁻⁶ in/in °F | µm/m °C |

| -423 | -200 | 4.7 | 10.1 |

| -300 | -100 | 5.8 | 11.3 |

| -200 | 20 | 6.2 | — |

| -100 | 100 | 6.3 | 13.3 |

| 0 | 200 | — | 13.9 |

| 70 | 300 | — | 14.2 |

| 200 | 400 | 7.4 | 14.8 |

| 400 | 500 | 7.7 | 15.3 |

| 600 | 600 | 8.0 | 15.5 |

| 800 | 700 | 8.3 | 15.8 |

| 1000 | 800 | 8.5 | 16.2 |

| 1200 | 900 | 8.7 | 16.6 |

| 1400 | 1000 | 8.9 | 16.9 |

| 1600 | 1100 | 9.1 | 17.1 |

| 1800 | 9.3 | ||

| 2000 | 9.5 |

|

|

|||

| Sulfuric Acid | Good | Organic Acids | Excellent |

| Phosphoric Acid | Good | Strong Alkalis | Excellent |

| Hydrochloric Acid | Good | Reducing Salts | Excellent |

| Hydrofluoric Acid | Excellent | Oxidizing Salts | Not recommended |

| Nitric Acid | Not Recommended | Seawater | Good |

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Nickel 200 | 2.4066 | N02200 | NW 2200 | NA 11 | НП-2 | N-100M | Ni 99.2 |