Contact

E-mail us

Nickel Alloy Plates, Nickel Metal, Nickel Plate Supplier, Nickel Plate Manufacturer, Nickel Plate In Mumbai, India, Nickel Plate For Sale

Table of Content

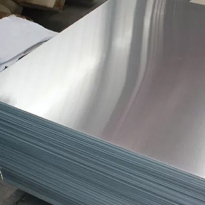

Nickel Alloy Plates are high-quality Nickel Metal sheets known for their excellent corrosion resistance, strength, and long-lasting durability. They provide continuous performance even under tough conditions, making them a dependable solution for varied industrial needs. Preston Pipes & Alloys is a reputable Nickel Plate Supplier, offering high-quality plates that meet stringent standards of quality. Our plates have precise dimensions, high material integrity, and consistent performance. As the leading supplier of nickel plate in Mumbai, India, we ensure that each plate maintains constant quality and long-term reliability. Our Nickel Alloy Plates are strong, pure, and versatile, meeting the industry's highest standards.

A nickel plate is a flat metal sheet manufactured from high-quality nickel alloy, which is often more than 99% pure nickel. It provides superior strength, corrosion resistance, and heat tolerance. Nickel plates handle acids, alkalis, and saltwater without corroding, making them ideal for chemical, marine, and industrial use. They are easy to bend, roll, and shape making them ideal for the accurate production of tanks, pipelines, and heat exchangers. The high purity ensures continuous performance and durability under difficult conditions.

The table below provides detailed specifications for various nickel alloy plates, including dimensions, grades, and applicable standards.

| Specification | ASTM B162 UNS N02200, ASME SB162 |

| Sizes | 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm |

| Thickness | 0.1mm to 100 mm Thk |

| Width | 10-2500mm |

| Length | 2m, 2.44m, 3m, or as required |

| ASTM | ASTM B168 |

| AMS | AMS 5553 |

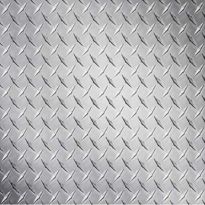

| Finish | Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) |

| Hardness | Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc. |

| Stock in form of | Nickel Plate, Sheet, Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Strip, Flats, Clad Plate, Rolling Sheet, Flat Sheet, Rolling Plate, Flat Shim, Blank (Circle), hot rolled, cold rolled, annealed, soft annealed, descaled, sheared, tread plate, Checker Plate |

| Material |

JIS: N0, N2, N1, NW2200, NW2201, NW4400, NW5500,

NW6002, etc DIN: H-Ni99.96, H-Ni99.95, H-Ni99.92, H-Ni99.90, H-Ni99.5, H-Ni99, etc |

| Why choose Superior Steel Overseas |

|

| Profiling |

To provide a full profiling service we use numerous profiling methods

including:

|

| Specialized in |

|

Buy Nickel Plate for High-Performance Corrosion-Resistant Alloy

Nickel plates have distinct properties that make them extremely reliable for industrial and engineering applications.

- High Strength: Nickel plates resist bending and breaking under heavy loads. They offer strong assistance even in high-pressure situations, ensuring safety and durability.

- Toughness: These plates can tolerate shocks, impacts, and unexpected forces without cracking. This makes them ideal for structural components exposed to stress.

- Good Hardness: Their firm surface resists wear, scratches, and abrasion. Components last longer and maintain performance under heavy use.

- Corrosion Resistance: Nickel plates can withstand rust and chemical damage in moist, salty, or acidic conditions. This keeps machinery and structures safe for years.

- Thermal Properties: They maintain their strength and shape under high heat. This makes them suitable for engines, furnaces, and other high-temperature systems.

- High-Temperature Stability: Even under extreme heat, nickel plates resist warping and softening. They ensure consistent performance in critical industrial applications.

- Low Thermal Expansion: Nickel plates expand extremely little when heated, allowing for accurate proportions. This prevents misalignment and increases efficiency in machines and tools.

- Electrical & Magnetic Properties: Nickel plates allow a smooth flow of electricity while supporting magnetic applications. They are suitable for reliable electrical and electronic components.

- Good Electrical Conductivity: They reduce energy loss and minimize heat buildup in circuits. This ensures stable performance in wiring, connectors, and electronic devices.

- Fabrication and Weldability: Nickel plates are easy to cut, shape, and weld. This flexibility saves time during manufacturing and allows precise assembly.

- Good Workability: They work well with machining, bending, and forming. Designers and engineers can craft complex shapes without compromising strength or quality.

This table shows the chemical composition of nickel plates, according to ASTM B162 standards, which includes nickel (Ni), carbon (C), iron (Fe), manganese (Mn), silicon (Si), copper (Cu) and sulfur. It guarantees that the material meets specific industry standards for corrosion resistance and strength.

| Grade | Ni+Co | Cu | Si | Mn | C | S | Fe |

| Ni201 | 99.0 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.02 | ≤0.01 | ≤0.40 |

| Ni200 | 99.0 | 0.20 | 0.30 | 0.30 | 0.15 | 0.01 | 0.40 |

This chart shows the essential mechanical parameters of nickel alloy plates such as tensile strength, yield strength, elongation and hardness.

| Tensile Strength | 450 MPa |

| Yield Strength | 275 MPa |

| Elongation | 45% |

| Hardness | 95 (HR B) max |

Nickel plates are available in several grades, with Nickel 200 and Nickel 201 being the most popular. Both offer strong corrosion resistance and handle heat well, making them reliable for industrial use.

Nickel 200 Plate

Nickel 200 is nearly pure nickel with very low carbon content, giving it outstanding corrosion resistance. It is resistant to acids, alkalis, and saltwater, making it an excellent choice for chemical processing and marine applications. The metal remains tough and ductile, so it can bend, roll, or shape without cracking. Industries use Nickel 200 plates for heat exchangers, pressure vessels, tanks, and piping systems. It also performs well in high-temperature settings handling thermal stress without losing strength.

Nickel 201 Plate

Similar to nickel 200, nickel 201 has significantly less carbon, which helps shield it from high-temperature breaking. This makes it ideal for environments with extreme heat or oxidizing conditions. The grade provides great mechanical strength while remaining corrosion resistant. Nickel 201 plates are widely used in furnaces, boilers, chemical plants, and industrial heat-treatment equipment. Its superior stress performance makes it the ideal choice for long-term, high-temperature applications.

The weight chart provides an easy reference to calculate the approximate weight of nickel plates based on their dimensions. This ensures accurate planning for handling, shipping, and installation.

| SIZE | NICKEL | ALLOY | ALLOY | ALLOY | ALLOY | ALLOY | ALLOY | ALLOY | ALLOY | ALLOY | ALLOY | ALLOY | SIZE |

| 200/1 | 400 | 600 | 601 | 625 | 718 | 800 | 825 | AL6XN | C276 | 20 | A286 | ||

| .125" | X | X | X | X | X | X | X | X | X | X | X | X | 3.18mm |

| .134" | X | 3.40mm | |||||||||||

| .156" | X | X | X | X | X | X | X | 3.96mm | |||||

| .187" | X | X | X | X | X | X | X | X | X | X | X | X | 4.75mm |

| .250" | X | X | X | X | X | X | X | X | X | X | X | X | 6.35mm |

| .312" | X | X | X | X | X | X | 7.92mm | ||||||

| .375" | X | X | X | X | X | X | X | X | 9.53mm | ||||

| .500" | X | X | X | X | X | X | X | X | X | X | X | X | 12.7mm |

| .625" | X | X | X | X | X | X | X | X | X | 15.9mm | |||

| .750" | X | X | X | X | X | X | X | X | X | 19.1mm | |||

| .875" | X | X | X | 22.2mm | |||||||||

| 1" | X | X | X | X | X | X | X | X | X | X | X | 25.4mm | |

| 1.125" | X | 28.6mm | |||||||||||

| 1.250" | X | X | X | X | X | X | X | 31.8mm | |||||

| 1.500" | X | X | X | X | X | X | X | 38.1mm | |||||

| 1.750" | X | 44.5mm | |||||||||||

| 2" | X | X | X | X | 50.8mm | ||||||||

| 2.500" | X | X | X | 63.5mm | |||||||||

| 3" | X | 76.2mm |

The weight chart allows you to easily calculate the approximate weight of nickel plates based on their measurements. This ensures precise planning for handling, shipping, and installation.

| Gauge | 30 | 26 | 24 | 22 | 20 | 18 | 16 | 14 | 12 | 11 | 10 | 9 | 8 | |

| Nickel | Weight (lb/ft2) | 0.756 | 1.008 | 1.26 | 1.512 | 2.016 | 2.52 | 3.15 | 4.41 | 5.04 | 5.67 | 6.93 | ||

This chart shows the rolling dimensions of nickel alloy plates, including length, width, and thickness variations. It enables manufacturers and engineers in selecting plates appropriate for rolling and forming procedures.

| Dimension (mm) | KG P/M2 |

| 0.5 * 1000 * 2000 | 4.5 |

| 0.7 * 1219 * 3048 | 6.3 |

| 0.9 * 1219 * 3048 | 8.1 |

| 1.2 * 1219 * 3048 | 10.8 |

| 1.6 * 1200 * 3048 | 14.4 |

| 2.0 * 1219 * 3048 | 18 |

| 3 * 1200 * 3000 | 27 |

| 3.18 * VARIOUS ANN | 28 |

The thickness chart highlights the available hot-rolled plate options and their tolerances. It is useful for applications that require precise thickness for structural or industrial purposes.

| Thickness (Inch) | 3/16 | 1/4 | 3/8 | 1/2 | 5/8 | 3/4 | 1 | 1 1/4 | 1 1/2 | 1 3/4 | 2 | 2 1/2 | 3 |

| Thickness (mm) | 4.8mm | 6.3 | 9.5 | 12.7 | 15.9 | 19 | 25.4 | 31.8 | 38.1 | 44.5 | 50.8 | 63.5 | 76.2 |

This chart provides the standard tolerances for nickel plates as per ASME SB162 specifications. It ensures compliance with industry standards and guarantees quality in critical applications.

| Grade | Pure Nickel Strip 99.6%/99.9% |

| Thickness | 0.02 to 2.50 mm |

| Tolerance | +/- 5% (special tolerances is available) |

| Width | Up to 350mm wide |

| Coil size | Up to 80kg without welds |

| Temper Ranges | Annealed to Full Hard |

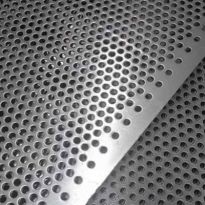

Nickel Alloy Plates are offered in a wide range of forms, including sheets, coils, strips, foils, shim stock, perforated sheets, clad plates, and both cold-rolled and hot-rolled plates, catering to diverse industrial applications with superior strength and corrosion resistance.

Nickel Sheet

Nickel Coil

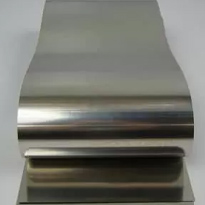

Nickel Strip

Nickel Foil

Nickel Shim Stock

Nickel Perforated Sheet

Nickel Clad Plate

Nickel Cold Rolled Plate