Contact

E-mail us

Inconel 600 Plate Suppliers, ASTM B168 Inconel 600 Sheet used for aerospace sectors, AMS 5540 Plates, UNS N06600 Strip in India

Table of Content

Inconel 600 Plate, offered by Preston Pipes and Alloys, is made from a high-performance nickel-chromium-iron alloy (UNS N06600) known for its excellent strength and corrosion resistance across a wide range of temperatures. These plates perform reliably from cryogenic conditions up to 1093°C (2000°F), making them suitable for extreme environments. The high nickel content in Inconel 600 provides outstanding resistance to reducing environments and protects against chloride stress corrosion cracking—a major benefit in chemical and marine applications. The added chromium enhances resistance in mild oxidizing conditions such as hot acids or steam.

Inconel 600 plates are non-magnetic and can be easily welded or fabricated using standard techniques. Their mechanical strength and ability to resist corrosion make them ideal for use in heat exchangers, chemical processing equipment, furnace parts, food industry machinery, and even components in nuclear power plants. These nickel alloy 600 plates maintain their structure and performance under pressure, heat, and chemical exposure, offering long-lasting reliability. At Preston Pipes and Alloys, we supply Inconel 600 plates in various sizes and finishes, tailored to suit both standard and custom industrial requirements.

Inconel 600 Plate Stockist, ASME SB168 Nickel Alloy 600 Coil, WNR 2.4816 Foil, Inconel 600 Shim Sheet

| Type | Plate, Sheet, Strip, Flats, Coils, Foils, Clad Plate, Rolls, Blank (Circle), Plain Sheet, Rolling Plate, Flat Sheet, Rolling Sheet, Shim Sheet, Flat Shim, sheared, annealed, descaled, soft annealed, tread plate, Checker Plate |

| ASTM B168 Alloy 600 Plate Length | 0-12mm or as required |

| 600 Inconel Plate Width | 0-2500mm or as required |

| ASTM B168 Alloy 600 Plate Thickness | 0.3 to 1200 mm or as required |

| UNS N06600 Plate Process | Hot/ Cold Rolled |

| Inconel 600 Plate surface | No.1, No.3, No. 2D, BA, No. 2B, No.6, 2B, No.7, No.4, 2D, (CR) Cold rolled sheet, No.1 finish hot rolled, 1D, SATIN (Met with Plastic Coated), ASTM B168 Alloy 600 Plate, No.4, 2B, 8K, BA, (HR) Hot rolled plate, satin, brush, hairline, mirror, BA No(8) etc. |

| 3/16" | 1/4" | 3/8" | 1/2" | 5/8" | 3/4" |

| 4.8mm | 6.3mm | 9.5mm | 12.7mm | 15.9mm | 19mm |

| 1" | 1 1/4" | 1 1/2" | 1 3/4" | 2" | |

| 25.4mm | 31.8mm | 38.1mm | 44.5mm | 50.8mm |

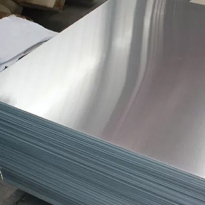

Inconel Alloy 600 Sheet

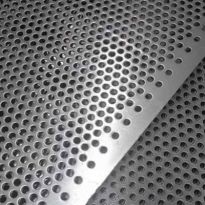

Inconel 600 Perforated Sheet

Inconel 600 Clad Plate

2.4816 Cold Rolled Sheet

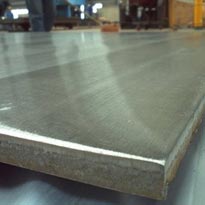

UNS N06600 Hot Rolled Plate

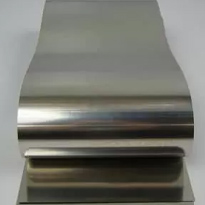

ASTM B168 Inconel 600 Strip

Inconel 600 Coil

Inconel 600 Foil

600 Inconel Shim Sheet

Alloy 600 Shim Stock

Get in touch with us for the best deal on Inconel 600 Plate

| Element | Content |

| Nickel (plus Cobalt) | 72.0 min. |

| Manganese | 1.00 |

| Chromium | 14.0 min. - 17.0 max. |

| Sulfur | 0.015 |

| Iron | 6.0 min. - 10.0 max. |

| Silicon | 0.50 |

| Carbon | 0.15 |

| Copper | 0.50 |

| Typical Values at 68°F [20°C] | ||||

| Yield Strength 0.2% Offset | Ultimate Tensile Strength | Elongation in 2" | ||

| psi | (MPa) | psi | (MPa) | % |

| 35,000 | (240) | 80,000 | (550) | 30 |

| Density |

0.304 lbs/in³ 8.42 g/cm³ |

| Specific Heat |

0.106 BTU/lb-°F (32–212°F) 444 J/kg-°K (0–100°C) |

| Modulus of Elasticity |

31.1 × 10⁶ psi 214 GPa |

| Thermal Conductivity 200°F (100°C) |

109 BTU/hr/ft²/ft/°F 15.9 W/m-°K |

| Melting Range |

2470 – 2575°F 1354 – 1413°C |

| Electrical Resistivity |

620 Microhm-in at 68°C 1.03 Microhm-cm at 20°C |

| Mean Coefficient of Thermal

Expansion Temperature Range |

|||

| °F | °C | in/in/°F | cm/cm°C |

| 68 | 20 | 5.8 x 10⁻⁶ | 10.4 x 10⁻⁶ |

| Size (in mm) | Size (in inches) |

| 3.40 | .134" |

| 3.18 | .125" |

| 4.75 | .187" |

| 3.96 | .156" |

| 7.92 | .312" |

| 6.35 | .250" |

| 12.7 | .500" |

| 9.53 | .375" |

| 19.1 | .750" |

| 15.9 | .600" |

| 25.4 | 1" |

| 22.2 | .875" |

| 31.8 | 1.250" |

| 28.6 | 1.125" |

| 44.5 | 1.750" |

| 38.1 | 1.500" |

| 63.5 | 2.500" |

| 50.8 | 2" |

| 76.2 | 3" |

Dimensions: widths 1000/1220/1500 mm, lengths 2000/2500/3000 mm.

| STANDARD | WERKST OFF NR. | UNS | JIS | AFNOR | BS | GOST | EN | OR |

| Inconel 600 | 2.4816 | N06600 | NCF 600 | NC15F E11M | NA 13 | МНЖ Мц 28-2,5-1,5 | NiCr 15Fe | ЭИ868 |