Contact

E-mail us

Inconel Alloy Plates, Inconel Metal, Inconel Plate Manufacturers, Inconel Plate Suppliers, Inconel Plate In Mumbai, Inconel Plate For Sale

Table of Content

Inconel Alloy Plates are high-performance nickel-chromium alloys known for their strength, high nickel content, and highly corrosion resistant nature, making them suitable for extreme industrial conditions. Preston Pipes & Alloys is a trusted name among Inconel Plate Manufacturers, delivering premium-quality Inconel Metal plates designed to meet diverse application needs. As a leading supplier of Inconel Plate in Mumbai, India, we provide plates that meet international standards, offering dependable performance and specifications, grades, sizes, properties, and types of plates for a wide range of industries.

An Inconel plate is a nickel-chromium alloy product made to perform in extreme conditions. It has a high nickel content with additional chromium, giving the plate both strength, and excellent corrosion resistant qualities. When exposed to heat, the plate forms a stable oxide layer that shields the surface. This makes it durable in chemical plants, marine settings, and high-temperature operations. Inconel plates also provide outstanding resistance to chloride stress corrosion cracking which is vital in saltwater and harsh chemical environments. The alloy keeps its strength across a wide temperature range. While other metals degrade under heat and pressure, Inconel plates remain strong under stress, making them an excellent choice for the aerospace, oil & gas, and power industries.

The Inconel Plate Specification table highlights critical information such as available thickness, width, length, and standard grades of Inconel plates. It helps you match your project needs with precise plate dimensions and configurations

| Property | Inconel Plate | Inconel Sheet | Inconel Coil | Inconel Strip |

| Thickness | 2.5 – 50 mm | ≤ 5 mm | 0.1 – 5.0 mm | 0.05 – 3 mm |

| Width | 50 – 1000 mm | 500 – 1000 mm | 0.5 – 1.2 m | 5 – 200 mm |

| Length | 100 – 6000 mm | 700 – 6000 mm | – | – |

| Quote | Quote within 24Hrs with Technical Data Sheet | |||

| Tested | 100% Tested Inconel Plate supply with MTC EN 10204/3.1 | |||

High-quality Inconel plates for sale at the best price – enquire now!

Inconel plates are known for their ability to perform in extreme conditions. They are a reliable option for demanding sectors, because they combine strength, corrosion resistance and dependability.

- High-Temperature Strength : Inconel plates hold their strength even at very high temperatures. This makes them reliable for furnaces, turbines, and aerospace components.

- Superior Corrosion Resistance : The high nickel and chromium content gives Inconel plates excellent corrosion resistance. They stand strong in seawater, acids, and harsh chemical environments.

- Good Weldability: Inconel plates can be welded using traditional processes without sacrificing strength. Proper welding methods result in strong joints and a long service life.

- Durability under Mechanical Stress : These plates can handle stress, pressure, and heavy loads without cracking. Their toughness makes them suitable for industries where both strength and safety matter.

The chemical properties table lists the composition of Inconel plates, including nickel, chromium, iron, and trace elements. The values shown characterize the alloy's corrosion resistance and high-temperature performance.

| Grade | Co | Mo | Fe | Cr | Nb | Ni | Ti | Mn | Al | Cu | Si | S | C | B | P |

| 600 | – | – | 6.0-10.0 | 14.0-17.0 | – | 72.0 | – | 1.0 | – | 0.5 | 0.5 | 0.015 | 0.15 | – | – |

| 617 | 10.0-15.0 | 8.0-10.0 | 3.0 | 20.0-24.0 | – | 44.2-56.0 | 0.6 | 0.5 | 0.8-1.5 | 0.5 | 0.5 | 0.015 | 0.15 | 0.006 | 0.015 |

| 625 | 1.0 | 8.0-10.0 | 5.0 | 20.0-23.0 | 3.15-4.15 | 58.0 | 0.4 | 0.5 | 0.4 | – | 0.5 | 0.015 | 0.1 | – | 0.015 |

| 718 | 1.0 | 2.8-3.3 | balance | 17.0-21.0 | 4.75-5.5 | 50.0-55.0 | 0.3 | 0.35 | 0.65-1.15 | 0.2-0.8 | 0.35 | 0.015 | 0.08 | 0.006 | 0.015 |

| X-750 | 1.0 | – | 5.0-9.0 | 14.0-17.0 | 0.7-1.2 | 70.0 | 2.25-2.75 | 1.0 | 0.4-1.0 | 0.5 | 0.5 | 0.01 | 0.08 | – | – |

The mechanical characteristics table displays the strength, hardness and elongation of Inconel plates. These values assist in selecting the appropriate grade for demanding industrial applications.

| Alloy | Tensile strength – MPa | Yield strength – MPa | Melting Range (℃) | Density | Brinell hardness (HB) | Elongation % |

| Alloy 600 | 550 min. | 240 min. | 1370–1425 ℃ | 8.4 g/cm³ | ≤195 | 30 min. |

| Alloy 601 | 650 min. | 300 min. | 1320–1370 ℃ | 8.1 g/cm³ | ≤220 | 30 min. |

| Alloy 625 | 760 min. | 345 min. | 1290–1350 ℃ | 8.4 g/cm³ | ≤220 | 30 min. |

| Nickel Alloy 718 | 965 min. | 550 min. | 1260–1340 ℃ | 8.2 g/cm³ | ≤363 | 30 min. |

Inconel plates come in different grades to handle heat, pressure, and corrosion. The Inconel alloy list includes grades 600, 601, 625, 718, 800, and 825. Each grade has its strengths that fit unique industrial needs.

Inconel 600 Plate

Inconel 600 plate offers strong resistance to heat and oxidation. It works well in high-temperature furnace parts, chemical processing, and nuclear power. This grade is also known for good strength and toughness across a wide temperature range.

Inconel 601 Plate

Inconel 601 plate is designed for high heat and oxidation resistance. It can withstand high furnace conditions, thermal processing, and petrochemical operations. It can also withstand spalling and scaling at high temperatures.

Inconel 625 Plate

Inconel 625 plate stands out for its corrosion resistance and toughness. It handles seawater, acidic conditions, and strong oxidizing agents. Common uses include marine, aerospace and chemical industries, where strength and durability matter.

Inconel 718 Plate

The strong strength of Inconel 718 plate at high temperatures is well-known. It maintains stability in aerospace engines, turbines and power plants. It is a versatile, high-performance alloy that also offers exceptional corrosion resistance.

Inconel 800 Plate

Inconel 800 plate offers strength and stability under high heat. It resists carburization and oxidation, making it appropriate for heat exchangers, furnace parts and petrochemical processes. It keeps its mechanical properties even at prolonged high temperatures.

Inconel 825 Plate

Inconel 825 plates are very resistant to strong acids such as sulfuric and phosphoric. It is commonly used in chemical facilities, pollution control, and oil and gas processing. This grade is chosen for its reliability in aggressive environments.

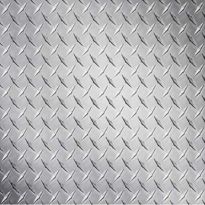

The thickness and size chart for Inconel plates provides details, on the available dimensions, ranging from standard thickness options to customized sizes.

| Width | Thickness Range |

| 1/4 inch (6.35 mm) | 0.010 inch (0.25 mm) to 0.250 inch (6.35 mm) |

| 1/2 inch (12.7 mm) | 0.020 inch (0.51 mm) to 0.500 inch (12.7 mm) |

| 1 inch (25.4 mm) | 0.030 inch (0.76 mm) to 0.750 inch (19.05 mm) |

| 2 inch (50.8 mm) | 0.040 inch (1.02 mm) to 1.000 inch (25.4 mm) |

| 3 inch (76.2 mm) | 0.050 inch (1.27 mm) to 1.500 inch (38.1 mm) |

| 4 inch (101.6 mm) | 0.060 inch (1.52 mm) to 2.000 inch (50.8 mm) |

| 6 inch (152.4 mm) | 0.070 inch (1.78 mm) to 2.500 inch (63.5 mm) |

| 8 inch (203.2 mm) | 0.080 inch (2.03 mm) to 3.000 inch (76.2 mm) |

| 10 inch (254 mm) | 0.090 inch (2.29 mm) to 4.000 inch (101.6 mm) |

| 12 inch (304.8 mm) | 0.100 inch (2.54 mm) to 5.000 inch (127 mm) |

Inconel plates come in a variety of grades and types each designed to endure certain industrial situations. These plates are suitable for a wide range of applications, including high-temperature alloys and corrosion-resistant grades. The choice of Inconel plate is determined by the application's strength, temperature resistance, and corrosion protection requirements.

Inconel Sheet

Inconel Coil

Inconel Strip

Inconel Foil

Inconel Shim Stock

Inconel Clad Plate

The ASTM standards for Inconel plates define the grades, specifications, and testing methods to ensure reliability and performance.

| Grade | ASTM Specification | ASTM Standard Covering details & Additional Processing |

| 600 | B168 |

|

| B409 |

|

|

| 601 | B168 |

|

| B409 |

|

|

| 625 | B443 |

|

| B444 |

|

|

| B453 |

|

|

| 718 | B670 |

ASTM B670 Inconel plate standard require following Additional Processing

|

| B637 |

|

|

| 690 | B466 |

|

| B167 |

|

|

| 740 | B446 |

|

| B167 |

|

|

| 783 | B446 |

|

| B167 |

|

|

| 792 | B446 |

|

| B167 |

|

|

| 909 | B446 |

|

| B167 |

|

FAQ

Inconel 718 – Offers superior high-temperature strength and is widely used in aerospace.

Inconel 825 – Ideal for acidic and chemical conditions due to its superior corrosion resistance.