Contact

E-mail us

Inconel 601 Plate Suppliers, ASTM B168 Inconel 601 Sheet, Alloy UNS N06601 Strip in India

Table of Content

Inconel 601 sheet, plate, and coil are high-performance nickel-chromium alloy products known for their excellent resistance to heat and corrosion. These materials hold up exceptionally well in extreme conditions especially at high temperatures. The alloy's strong chemical makeup includes nickel, chromium, and iron, offering protection against oxidation and carburization. While Inconel 601 plate offers strength and durability for industrial equipment, Inconel 601 sheet is perfect for structures exposed to heat. Inconel 601 coil is widely used in applications that require both corrosion resistance and high-temperature performance. Preston Pipes and Alloys supplies these products in different sizes and forms to meet industry-specific needs.

Industries such as petrochemicals, gas processing, power generation, condensers, heat exchangers, and seawater equipment all benefit from Inconel 601's performance. It can handle temperatures up to 1250°C, even with repeated heating and cooling. Its high chromium and aluminum content protect against oxidation, especially in sulfur-rich environments. Because of its capacity to form a stable oxide layer the alloy is resistant to corrosion in applications involving thermal processing. It also holds up against carburization, making it dependable for high-temperature service. With strong weldability and good formability it can be shaped easily. The non-magnetic property of Inconel 601 is crucial in settings where magnetic fields are present. Its longevity promotes sustainable operations and reduces maintenance expenses.

Preston Alloys offers Inconel 601 sheet, plate, and coil in sizes like 1000mm x 2000mm, 1500mm x 3000mm, and 2000mm x 4000mm. Thickness ranges from 0.1mm to 12mm. These products come in hot rolled and cold rolled finishes. Surface types include soft, half hard, quarter hard, hard, and spring hard. The materials are made under strict manufacturing processes and checked for consistent thickness and surface finish. Each product is built to meet industry demands for strength, corrosion resistance, and thermal stability. Every item undergoes inspection to ensure it meets customer expectations.

Each Inconel 601 sheet, plate, and coil goes through mechanical testing, chemical analysis, and non-destructive tests like PMI and IGC. These ensure the product's integrity and performance. Standards like ASTM B168 and SB 168 apply. Products are packed in poly bags, then placed in wooden crates or pallets for safe delivery. Preston Alloys includes all required documents for smooth shipping. These steps ensure clients get high-quality, damage-free materials ready for use in critical applications.

Alloy 601 Plates Stockist in Mumbai, ASME SB168 Nickel Alloy 601 Coil, WNR 2.4851 Foil, Inconel 601 Shim Stock

| Standard | ASTM B168 / ASME SB168 |

| Material Grade | Inconel 601 (UNS N06601, W.Nr. 2.4851) |

| Size | 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm |

| Thickness Range | 0.3 to 1200 mm or as required |

| Length | 2000 mm to 6000 mm (cut-to-size available) |

| Technique | Hot Rolled, Cold Rolled, Forged |

| Hardness | Soft, hard, half hard, spring hard (as required) |

| Form | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Strip, Flats, Blank (Circle) |

| Packing | Packed in Wooden Boxes, Bubble wraps, Steel Strips Bundled, or as per Customers Requests |

| Testing and Documents | Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, Destructive Test Report, Non Destructive Test Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports |

| Size (inches) | Size (mm) |

| 3/16" | 4.8 mm |

| 1/4" | 6.3 mm |

| 3/8" | 9.5 mm |

| 1/2" | 12.7 mm |

| 5/8" | 15.9 mm |

| 3/4" | 19 mm |

| 1" | 25.4 mm |

| 1 1/4" | 31.8 mm |

| 1 1/2" | 38.1 mm |

| 1 3/4" | 44.5 mm |

| 2" | 50.8 mm |

| Gauge | 14 | 8 | 26 | 16 | 24 | 18 | 11 | 20 | 22 | 12 | 10 |

| Weight (lb/ft²) | 3.15 | 6.93 | 0.756 | 2.52 | 1.008 | 2.016 | 5.04 | 1.512 | 1.26 | 4.41 | 5.67 |

| Thickness (inch) | Thickness (mm) |

| 1 3/4 | 44.5 |

| 1 | 25.4 |

| 2 | 50.8 |

| 3 | 76.2 |

| 3/16 | 4.8 |

| 1/4 | 6.3 |

| 3/8 | 9.5 |

| 1/2 | 12.7 |

| 5/8 | 15.9 |

| 1 1/2 | 38.1 |

| 2 1/2 | 63.5 |

| 3/4 | 19 |

| 1 1/4 | 31.8 |

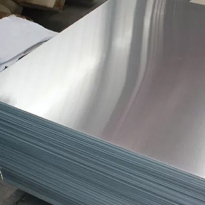

Inconel 601 Sheet Metal

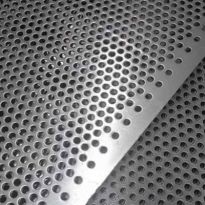

ASTM B168 Type 601 Perforated Sheet

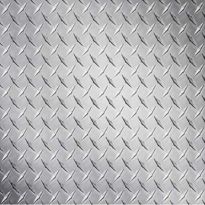

Inconel 601 Chequered Plate

Inconel 601 Plain Sheet

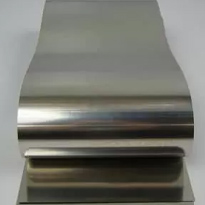

Inconel 601 Cold Rolled Sheet

UNS N06601 Hot Rolled Plate

Inconel 601 Strip

Inconel 601 Coil

Inconel 601 Foil

Inconel 601 Shim Sheet

Inconel 601 Shim Stock

Get in touch with us for the best deal on Inconel 601 Sheet, Plate and Coil

| Element | Content |

| Nickel | 58.0 – 63.0 |

| Chromium | 21.0 – 25.0 |

| Iron | Remainder |

| Aluminum | 1.0 – 1.7 |

| Carbon | 0.10 max. |

| Manganese | 1.0 max. |

| Sulfur | 0.015 max. |

| Silicon | 0.50 max. |

| Copper | 1.0 max. |

| Form and Condition | Hardness, Rb | Tensile Strength (ksi) | Tensile Strength (MPa) | Yield Strength (ksi) | Yield Strength (MPa) | Elongation (%) |

| Rod and Bar, Hot-Finished | 85–120 | 85–120 | 585–825 | 35–100 | 240–690 | 60–15 |

| Rod and Bar, Annealed | 80–115 | 80–115 | 550–790 | 30–60 | 205–415 | 70–40 |

| Plate, Annealed | 80–100 | 80–100 | 550–690 | 30–45 | 205–310 | 65–45 |

| Sheet, Cold-Rolled | 115–190 | 115–190 | 790–1310 | 100–175 | 690–1205 | 20–2 |

| Sheet, Annealed | 85–100 | 85–100 | 585–690 | 30–50 | 205–345 | 55–35 |

| Strip, Cold-Rolled | 115–190 | 115–190 | 790–1310 | 100–175 | 690–1205 | 20–2 |

| Strip, Annealed | 85–100 | 85–100 | 585–690 | 30–50 | 205–345 | 55–35 |

| Property | Value |

| Density | 8.1 g/cm³ |

| Melting Range | 1360–1411 °C |

| Specific Heat (21 °C) | 448 J/kg·°C |

| Curie Temperature | < –196 °C |

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Inconel 601 | 2.4851 | N06601 | NCF 601 | NA 49 | XH60BT | NC23FeA | NiCr23Fe |