Contact

E-mail us

Inconel 718 Plate Suppliers in India, ASTM B670 Inconel 718 Sheet, Alloy UNS N07718 Coil in Mumbai

Table of Content

A nickel-chromium-based superalloy with exceptional strength, stability, and resistance to corrosion, Inconel 718 is available in sheet, plate, and coil form. These products are commonly used in aerospace, oil & gas, and power generation. Preston Pipes and Alloys manufactures and supplies Inconel 718 sheet, Inconel 718 plate, and Inconel 718 coil with consistent quality and precision. The alloy contains nickel (50–55%), chromium (17–21%), and small amounts of manganese, silicon, carbon, and copper. It provides 45% elongation, a yield strength of 75,000 psi, and a tensile strength of 135,000 psi. With a density of 8.2 g/cm³ and melting point of 1350°C, this material delivers excellent mechanical properties even under stress. The Inconel 718 sheet is thin and flexible, the thicker Inconel 718 plate for load bearing components and the rolled Inconel 718 coil are all suitable for continuous use in manufacturing lines.

High tensile and creep-rupture strength, resistance to corrosion in challenging conditions, and resistance to oxidation at high temperatures are some of the alloy's primary characteristics. It's also weldable and formable, which helps in complex manufacturing tasks. Because of these benefits, alloy 718 sheet and alloy 718 plate are trusted in gas turbines, base plates, jet engine parts, rotor bolts, and burst discs. The Inconel 718 coil supplier market continues to grow with its increasing use in aerospace frames, oil field equipment, and chemical processing units. This alloy holds up well under pressure, temperature, and corrosion, making it ideal for critical applications like cryogenic storage tanks, valves, and high-speed airframe components.

The material is manufactured as per ASTM B670 and B424 standards and meets ASME SB 670 and SB 424 requirements. These forms come in custom thicknesses and widths depending on project needs. Sheets range from 0.5 mm to 3 mm, plates go up to 100 mm, and coils are supplied in varying lengths and widths. The Inconel 718 plate stock includes hot-rolled and cold-rolled options based on end-use. The manufacturing techniques used ensure tight tolerances and uniform grain structure for top performance. Demand for Inconel 718 plate suppliers continues to rise with growing industrial use.

All products go through strict quality checks. Tests include ultrasonic, hardness, mechanical, and chemical composition verification. At every stage, we inspect for dimensional accuracy and finish. We package all Inconel 718 sheet stockist and coil material in secure wrapping to avoid damage during transit. Export packaging meets international safety and compliance norms. Whether you're sourcing for aerospace or oil & gas, Preston Alloys ensures reliable delivery, competitive Inconel 718 plate price, and ready availability of stock.

AMS 5596 Nickel Alloy 718 Plates Stockist, ASME SB670 Alloy 718 Strip, WNR 2.4668 Foil, Inconel 718 Shim Stock

| Property | Details |

| Standard | ASTM B670 / ASME SB670, AMS 5596, AMS 5597, GE B50TF14 |

| Material Grade | Inconel 718 (UNS N07718, W.Nr. 2.4668) |

| Size | 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm |

| Thickness Range | 0.3 to 1200 mm or as required |

| Length | 2000 mm to 6000 mm (cut-to-size available) |

| ASTM B670 Alloy 718 Plate Process | Hot Rolled, Cold Rolled |

| Hardness | Soft, Hard, Half Hard, Spring Hard (as required) |

| Form | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Strip, Flats, Blank (Circle) |

| Packing | Packed in Wooden Boxes, Bubble Wraps, Steel Strips Bundled, or as per Customer Requests |

| Testing and Documents | Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, Destructive Test Report, Non-Destructive Test Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports |

| Size (inches) | Size (mm) |

| 3/16" | 4.8 mm |

| 1/4" | 6.3 mm |

| 3/8" | 9.5 mm |

| 1/2" | 12.7 mm |

| 5/8" | 15.9 mm |

| 3/4" | 19 mm |

| 1" | 25.4 mm |

| 1 1/4" | 31.8 mm |

| 1 1/2" | 38.1 mm |

| 1 3/4" | 44.5 mm |

| 2" | 50.8 mm |

| Size (inches) | Size (mm) |

| .125" | 3.18 mm |

| .134" | 3.40 mm |

| .156" | 3.96 mm |

| .187" | 4.75 mm |

| .250" | 6.35 mm |

| .312" | 7.92 mm |

| .375" | 9.53 mm |

| .500" | 12.7 mm |

| .600" | 15.9 mm |

| .750" | 19.1 mm |

| .875" | 22.2 mm |

| 1" | 25.4 mm |

| 1.125" | 28.6 mm |

| 1.250" | 31.8 mm |

| 1.500" | 38.1 mm |

| 1.750" | 44.5 mm |

| 2" | 50.8 mm |

| 2.500" | 63.5 mm |

| 3" | 76.2 mm |

Dimensions: widths 1000/1220/1500 mm, lengths 2000/2500/3000 mm

Inconel 718 Sheet Metal

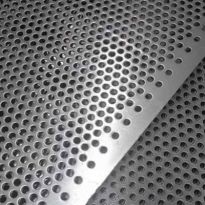

ASTM B670 Type 718 Perforated Sheet

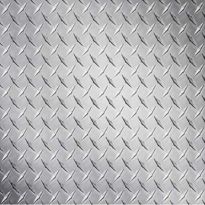

Inconel 718 Chequered Plate

Inconel 718 Plain Sheet

Inconel 718 Cold Rolled Sheet

UNS N07718 Hot Rolled Plate

Inconel 718 Strip

Inconel 718 Coil

Inconel 718 Foil

Inconel 718 Shim Sheet

Inconel 718 Shim Stock

Get in touch with us for the best deal on Inconel 718 Sheet, Plate and Coil

| Element | Ni | Cr | Fe | Mo | Nb+Ta | C | Mn | Si | P | S | Ti | Cu | B | Al | Co |

| Min | 50 | 17 | Bal | 2.8 | 4.75 | - | - | - | - | - | 0.65 | - | - | 0.20 | - |

| Max | 55 | 21 | - | 3.3 | 5.50 | 0.08 | 0.035 | 0.35 | 0.015 | 0.015 | 1.15 | 0.30 | 0.006 | 0.80 | 1.00 |

annealed condition

| 0.2% Proof Stress | Tensile Strength | Elongation | |

| MPA | MPA | % | |

| Max | Max | Min | |

| Sheet and strip | 550 | 965 | 30 |

| Plate | 725 | 1035 | 30 |

Heat Treated Condition

| 0.2% Proof Stress | Tensile Strength | Elongation |

| MPA | MPA | % |

| Min | Min | Min |

| 1035 | 1240 | 12 |

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Inconel 718 | 2.4668 | N07718 | – | – | – | – | – |

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Inconel 718 | 2.4668 | N07718 | – | – | – | – | – |