Contact

E-mail us

Inconel 625 Plate Suppliers, ASTM B443 UNS N06625 Strip, Nickel Alloy 625 Sheet in Grades 1 and 2

Table of Content

Inconel 625 Plate is a high-performance nickel-based alloy plate known for its excellent strength, corrosion resistance, and reliability in extreme environments. Made from nickel, chromium, molybdenum, and niobium, this alloy offers outstanding resistance to pitting, crevice corrosion, and chloride stress corrosion cracking. Inconel 625 maintains its strength across a wide temperature range, from cryogenic levels up to 982°C (1800°F), without needing precipitation-hardening treatments. Its superior oxidation and carburization resistance make it ideal for high-temperature applications in the aerospace, marine, and chemical industries.

Preston Pipes and Alloys supplies Inconel 625 plates in various sizes and thicknesses, meeting international standards like ASTM B443 UNS N06625. These plates are also used in offshore oil drilling, heat exchangers, structural components, and custom fabrication projects due to their weldability, durability, and performance in demanding conditions. Inconel 625 plate price depends on the size, thickness, and specific requirements of the buyer. Contact us to get the latest pricing and availability based on your project needs.

Inconel 625 Plate Stockist, AMS 5599 Inconel 625 Sheet, Buy AMS 5599 Foil, WNR 2.4856 Coil

| Inconel 625 Sheet Sizes |

|

| WNR 2.4856 Plate Sizes |

|

| AMS 5599 Coil Sizes |

|

| Inconel 625LCF Strip Sizes |

|

| Inconel 625 Plate Edges |

|

| UNS N06625 Plate Physical Properties |

|

| Global Standards |

|

| Werkstoff 2.4856 Coil Origin |

|

| Nickel Alloy 625 Sheet Welding |

|

| Inconel 625LCF Strip Cutting |

|

| AMS 5599 Plate Technique |

|

| Alloy 625 Sheet Form |

|

| Alloy 625 Plate Hardness |

|

| Inconel 2.4856 Strip Process |

|

| AMS 5599 Sheet Applications |

|

| DIN 2.4856 Plate Finish |

|

| WNR 2.4856 Cold Rolled Plate Services |

|

| UNS 6625 Sheet Testing |

|

| Inconel 2.4856 Strip Documentation |

|

| AMS 5869 Cold Rolled Plate Marking |

|

| 3/16" | 1/4" | 3/8" | 1/2" | 5/8" | 3/4" | 1" |

| 4.8mm | 6.3mm | 9.5mm | 12.7mm | 15.9mm | 19mm | 25.4mm |

| 1 1/4" | 1 1/2" | 1 3/4" | 2" | 2 1/2" | 3" | |

| 31.8mm | 38.1mm | 44.5mm | 50.8mm | 63.5mm | 76.2mm |

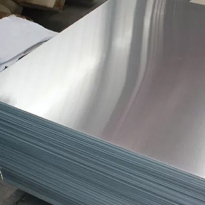

Inconel Alloy 625 Sheet

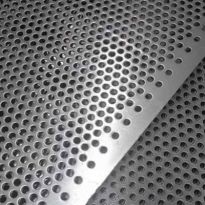

Inconel 625 Perforated Sheet

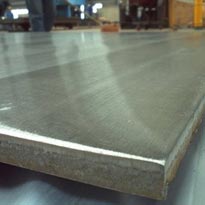

Inconel 625 Clad Plate

2.4816 Cold Rolled Sheet

UNS N06625 Hot Rolled Plate

ASTM B443 Inconel 625 Strip

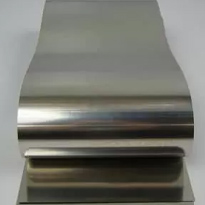

Inconel 625 Coil

Inconel 625 Foil

625 Inconel Shim Sheet

Alloy 625 Shim Stock

Get in touch with us for the best deal on Inconel 625 Plate

| Nickel | 58.0 min. | Silicon | 0.50 |

| Chromium | 20.0 min.-23.0 max. | Phosphorus | 0.015 |

| Molybdenum | 8.0 min.-10.0 max. | Sulfur | 0.015 |

| Iron | 5.0 | Aluminum | 0.40 |

| Niobium (plus Tantalum) | 3.15 min.-4.15 max. | Titanium | 0.40 |

| Carbon | 0.10 | Cobalt (if determined) | 1.0 |

| Manganese | 0.50 |

| Yield Strength 0.2% Offset | Ultimate Tensile Strength | Elongation in 2" | Hardness | ||

| psi (min.) | (MPa) | psi (min.) | (MPa) | % (min.) | (max.) |

| 65,000 | 448 | 125,000 | 862 | 50 | 200 Brinell |

| Density |

0.305 lbs/in³ 8.44 g/cm³ |

| Specific Heat |

0.102 BTU/lb-°F (32–212°F) 427 J/kg-°K (0–100°C) |

| Modulus of Elasticity |

30.1 × 106 psi 207.5 GPa |

| Thermal Conductivity 200°F (100°C) |

75 BTU/hr/ft²/ft/°F 10.8 W/m-°K |

| Melting Range |

2360 – 2460°F 1290 – 1350°C |

| Electrical Resistivity |

50.8 Microhm-in at 70°C 128.9 Microhm-cm at 20°C |

| Mean Coefficient of Thermal

Expansion Temperature Range |

|||

| °F | °C | in/in/°F | cm/cm°C |

| 200 | 93 | 7.1 x 10-6 | 12.8 x 10-6 |

| 400 | 204 | 7.3 x 10-6 | 13.1 x 10-6 |

| 600 | 316 | 7.4 x 10-6 | 13.3 x 10-6 |

| 800 | 427 | 7.6 x 10-6 | 13.7 x 10-6 |

| 1000 | 538 | 7.8 x 10-6 | 14.0 x 10-6 |

| 1200 | 649 | 8.2 x 10-6 | 14.8 x 10-6 |

| 1400 | 760 | 8.5 x 10-6 | 15.3 x 10-6 |

| 1600 | 871 | 8.8 x 10-6 | 15.8 x 10-6 |

| 1700 | 927 | 9.0 x 10-6 | 16.2 x 10-6 |

| Temperature Range | |||

| cm/°C | in/°F | °C | °F |

| 12.8 x 10-6 | 7.1 x 10-6 | 93 | 200 |

| 13.1 x 10-6 | 7.3 x 10-6 | 204 | 400 |

| 13.3 x 10-6 | 7.4 x 10-6 | 316 | 600 |

| 13.7 x 10-6 | 7.6 x 10-6 | 427 | 800 |

| 14.0 x 10-6 | 7.8 x 10-6 | 538 | 1000 |

| 14.8 x 10-6 | 8.2 x 10-6 | 649 | 1200 |

| 15.3 x 10-6 | 8.5 x 10-6 | 760 | 1400 |

| 15.8 x 10-6 | 8.8 x 10-6 | 871 | 1600 |

| 16.2 x 10-6 | 9.0 x 10-6 | 927 | 1700 |

| Width (mm) | Mill edge | Trimmed edge | ||

| Minus | Plus | Minus | Plus | |

| w > 1500 | 0 | 20 | 0 | 5 |

| 1200 < w ≤ 1500 | 0 | 20 | 0 | 5 |

| w ≤ 1200 | 0 | 20 | 0 | 3 |

| Grade | UNS | EN | Werkstoff NR. | JIS | GOST | BS | AFNOR |

| Inconel 625 | N06625 | NiCr22Mo9Nb | 2.4856 | NCF 625 | ХН75МБТЮ | NA 21 | NC22DNb4MNiC/22Mo9Nb |