Contact

E-mail us

Monel Alloy Plates, Monel Metal, Monel Plate Supplier, Monel Plate Manufacturer, Monel Plate In Mumbai, India, Monel Plate For Sale

Table of Content

Monel Alloy Plates are high-performance nickel-copper alloys known for their excellent resistance to corrosion, strength and durability, making them ideal for demanding industrial environments. Preston Pipes & Alloys is a known Monel Plate Supplier, delivering premium-quality Monel Plate designs for varied industrial needs. With a strong presence as a leading supplier of Monel Plate in Mumbai, India, we assure that plates meet international standards, providing dependable, versatile and long-lasting performance in a wide range of applications.

Monel plates are high-performance metal plates made from a nickel-copper alloy. This strong alloy consisting of around 63% nickel and 30% copper, along with other elements that enhance its properties. It is a high-performance nickel alloy that stands up to harsh conditions. It provides exceptional heat resistance, and outstanding corrosion resistance. Monel plates are known for their outstanding strength and ductility. They are used in demanding applications like marine environments and industrial components.

| Specifications | ASTM B127 / ASTM B164 / ASME SB164 / ASTM SB127 |

| Size | 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm |

| Thickness | 0.5 mm to 100 mm Thk |

| Form | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Strip, Flats, Blank (Circle), Ring (Flange) |

| Finish | Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA, NO(8), SATIN, Pickled & Passivated, Plastic Coated |

| Hardness | Soft, Hard, Half Hard, Quarter Hard, Spring Hard, Annealed, Tempered |

| Grade | Monel 400, Monel K-500, Monel R-405 |

| Density | 8.80 g/cm³ |

| Melting Point | 1300 – 1350 °C |

High-Strength Corrosion-Resistant Monel Plates at best price in India

Monel plates offer unique features that make them ideal for a variety of applications. This nickel-copper alloy provides an excellent balance of strength, resistance, and flexibility.

- Corrosion Resistance: Monel plates handle harsh environments very well, and they resist corrosion from saltwater, acids, and alkalis which makes them perfect for marine and chemical industry parts.

- Non-magnetic: This material is naturally non-magnetic, which is useful for sensitive electrical and electronic applications. It guarantees dependable performance and avoids interference.

- Temperature Resistance: Monel plates are extremely ductile, allowing them to be easily molded, and sculpted. The plates may be bent and drawn into different shapes without breaking.

- Ductility: The alloy supports standard welding methods without cracking or losing properties. This helps in building secure joints for long-term use.

- Weldability: Monel plates are easy to weld as they are compatible with a wide range of typical welding procedures. This allows for strong, dependable joints in complex systems.

- Strength and Durability: Monel plates are extremely strong and durable. It can handle stress and wear over time. The excellent strength-to-weight ratio enables long-term performance in demanding applications.

The chemical properties show the exact mix of nickel, copper and other elements that give Monel Plates their strength and corrosion resistance. The table lists the detailed composition for better clarity.

| C | Mn | Si | S | Cu | Fe | Ni |

| 0.30 max | 2.00 max | 0.50 max | 0.024 max | 28.00 – 34.00 | 2.50 max | 63.00 min |

The mechanical properties table highlights parameters such as tensile strength, yield strength, hardness, and elongation, which show how Monel Plates function under various conditions.

| Tensile strength, Yield | Tensile strength, Ultimate | Elongation at Break |

| 240 MPa | 550 MPa | 48% |

Monel plates are mainly available in two popular grades. Both deliver strong corrosion resistance and reliable performance, but each fits different needs.

Monel 400 Plate

Monel 400 Plate is a solid nickel-copper alloy with about 67% nickel and 23–34% copper. It resists seawater, acids, and alkalis, which makes it a trusted choice in marine engineering, pumps, heat exchangers, and chemical plants. The plate remains durable even in cold temperatures and is simple to form and weld. Due to its strength-to-flexibility ratio it is frequently used in many industries.

Monel K-500 Plate

Monel K-500 Plate takes the same base as Monel 400 but adds aluminum and titanium. This gives it higher strength, hardness and wear resistance while maintaining the same corrosion protection. It’s widely used in oil drilling tools, marine shafts, fasteners, and valve parts where durability under pressure matters most.

Monel 400 plate sizes are offered in standard sheet widths and lengths, with thickness options often in hot- or cold-rolled forms, so selecting the right size for your project feels easy.

| Size in mm | Size in Inch |

| 12.7mm | .500" |

| 25.4mm | 1" |

| 22.2mm | .875" |

| 7.92mm | .312" |

| 63.5mm | 2.500" |

| 19.1mm | .750" |

| 6.35mm | .250" |

| 31.8mm | 1.250" |

| 3.40mm | .134" |

| 3.18mm | .125" |

| 4.75mm | .187" |

| 38.1mm | 1.500" |

| 9.53mm | .375" |

| 15.9mm | .625" |

| 50.8mm | 2" |

| 76.2mm | 3" |

| 3.96mm | .156" |

| 28.6mm | 1.125" |

| 44.5mm | 1.750" |

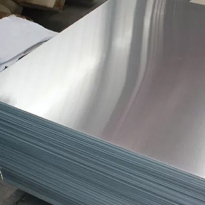

Monel Sheet

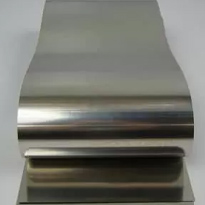

Monel Coil

Monel Strip

Monel Foil

Monel Shim Stock

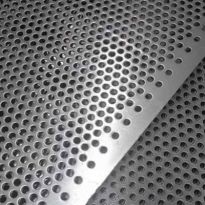

Monel Perforated Sheet

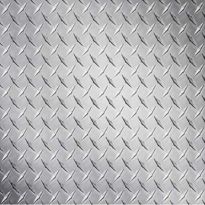

Monel Clad Plate

Monel Cold Rolled Plate

Monel Hot Rolled Plate

The table lists the common ASTM specifications and UNS designations for different Monel grades, covering standards like ASTM B127 for plates and sheets.

| Trade Name | ASTM/AISI Alloy type | UNS | %Cu | %Al | %Ti | %Fe | %Mn | %Si | %Ni |

| Monel 400 | B 127, B 164 | N04400 | 28–34 | - | - | 2.5 max | 2.0 max | 0.5 max | 63 min |

| Monel 401 | - | N04401 | 28–34 | - | - | 2.5 max | 2.0 max | - | 63 min |

| Monel 404 | - | N04404 | Rem | 0.05 max | - | 0.5 max | 0.1 max | 0.1 max | 52–57 |

| Monel K-500 | B 865 | N05500 | 27–33 | 2.3–3.15 | 0.35–0.85 | 2.0 max | 1.5 max | 0.5 max | 63 min |

| Monel 405 | B 164 | N04405 | 28–34 | - | - | 2.5 max | 2.0 max | 0.5 max | 63 min |

Monel, a nickel-copper alloy, comes in several forms based on thickness and end-use. All three sheets, plate, and foil carry the same corrosion resistance and strength, but their dimensions and applications vary.

Monel Sheet

Monel sheet usually ranges from 0.5 mm to 6 mm in thickness. It combines strength and flexibility, making it ideal for marine fittings, chemical processing units and heat exchangers. Its formability enables simple production of complicated shapes.

Monel Plate

Monel plate is the thickest form, often measuring more than 6 mm in thickness. It is intended for heavy-duty use and is extremely durable in seawater, acidic environments, and high-pressure applications.

Monel Foil

Monel foil is the thinnest variation, generally below 0.2 mm in thickness. It is perfect for gaskets, shielding and precise parts in electronics and aerospace as it is lightweight and resistant to corrosion.

FAQ

- Strong oxidizing chemicals like nitric acid should be avoided.

- Use fresh water, mild detergents, and alkaline cleaners.