Contact

E-mail us

ASTM B729, B468 Alloy 20 Tubes Supplier in Mumbai India. ASME SB729, B468 Alloy 20 Seamless, Welded, ERW Tubes ASTM B729 Incoloy alloy 20 ERW Tubing Supplier in Mumbai India.

Table of Content

Alloy 20 tubes are corrosion-resistant nickel-based tubing made with a mix of chromium, molybdenum, copper, and iron. These tubes are designed to perform in harsh environments, especially where sulfuric acid is present. Their strength and resistance come from the balanced composition and strong mechanical properties like high tensile strength and excellent elongation. Preston Pipes & Alloys is a leading Alloy 20 tube supplier known for providing top-quality tubing that meets demanding standards. The tubes are tested for reliable density, high melting point, and solid yield performance to ensure they work well in high-stress environments.

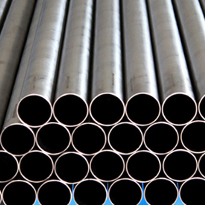

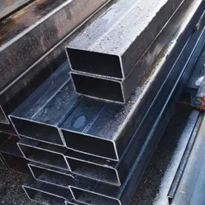

Alloy 20 tubes come in a wide range of sizes and finishes. Thickness ranges from 0.3 mm to 50 mm, with pressure schedules like SCH 5 to SCH XXS. Outside diameters go up to 914.4 mm, covering sizes up to 24” NB. These tubes are available in seamless, ERW, welded, CDW, and fabricated types. Shapes include round, square, rectangular, “U” shaped, coiled, and pancake coils. Buyers can get lengths in single random, double random, or custom sizes. Tube ends are supplied plain, beveled, or threaded, depending on the project needs.

Alloy 20 tubing is built to handle aggressive chemicals, especially sulfuric acid. That makes it ideal for use in the chemical, food, pharmaceutical, plastics, and power industries. The tubes resist pitting, stress cracking, and general corrosion. Because of these features, they’re often used in heat exchangers, process piping, mixing tanks, and pickling equipment. The tubing helps minimize downtime in essential components by operating effectively in both hot and cold environments.

Hydro, PMI, hardness, and third-party inspection reports are among the extensive tests that are performed on each tube. Quality control measures confirm the material is up to global standards of strength, corrosion resistance and durability. Packaging follows global export standards with wooden boxes and end caps for protection. As trusted Alloy 20 tube suppliers and Alloy 20 tube stockist, all orders are handled with care from start to finish. Get in touch for reliable tubing built for tough jobs.

| Specifications | ASTM B729 ASME SB729 / ASTM B468 ASME SB468 |

| Standard | ASTM, ASME and API |

| Dimensions | 4 to 219mm W. T.: 0.5 to 20mm |

| Schedule | SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH120, SCH140, SCH160, XXS |

| Type | Seamless / ERW / Welded / Fabricated |

| Form | Round, Hydraulic Etc |

| Length | Within 13500mm |

| End | Plain End, Beveled End, Treaded |

Alloy 20 Seamless Tube

Alloy 20 Welded Tube

Alloy 20 ERW Tube

Alloy 20 EFW Tube

Alloy 20 Round Tube

Alloy 20 Square Tube

Alloy 20 Rectangular Tube

Alloy 20 Polished Tube

Contact Preston Pipes and Alloys for best offer & competitive

quotation of Alloy 20 Tubes

| Grade | Ni | C | Mo | Mn | Si | Fe | Cu | S | P | Cr |

| Alloy 20 | 32 – 38 | 0.02 max | 2 – 3 | 1 – 2 | 0.7 max | Bal | 3 – 4 | 0.005 max | 0.02 max | 19 – 21 |

| Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 8.1 g/cm3 | 1443 °C (2430 °F) | Psi – 35000 , MPa – 241 | Psi – 80000 , MPa – 551 | 30 % |

| STANDARD | UNS | WERKSTOFF NR. | AFNOR | EN |

| Alloy 20 | N08020 | 2.4660 | Z2NCUD31-20AZ | NiCr20CuMo |