Contact

E-mail us

ASTM A249 SMO 254 Tubes Supplier in Mumbai India. ASME SA249, A269 254 SMO Seamless, Welded, ERW Tubes ASTM A249 SMO 254 ERW Tubing Supplier in Mumbai India.

Table of Content

SMO 254 tubes are high-alloy austenitic stainless steel tubes known for excellent strength and corrosion resistance. They contain elements like carbon, silicon, manganese, phosphorus, sulfur, chromium, nickel, molybdenum, nitrogen, and copper, which together offer great mechanical stability and durability. These tubes perform well under extreme conditions, especially in environments with seawater or high chloride levels. Preston Pipes & Alloys, a trusted supplier of stainless steel products, provides premium SMO 254 tubes for demanding uses. These tubes have an elongation of up to 35%, a yield strength of 300 MPa, and a tensile strength of 650 MPa. As their melting points range from 1320°C to 1390°C, it possess a high thermal resistance

254 SMO stainless steel tubes offer exceptional resistance to pitting, crevice corrosion, and stress corrosion cracking. This makes them ideal for use in systems that handle seawater, including cooling water lines, ballast water systems, firefighting networks, and other offshore structures. SMO 254 tubing is also utilized in gas cleaning units, hydraulic, and monitoring systems, bleaching equipment in pulp factories, and chemical containers handling substances that are halide-rich. This alloy is reliable in various industries that require long-lasting tubing solutions due to its high strength and resistance to corrosion.

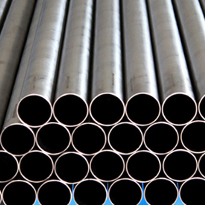

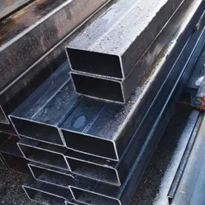

SMO 254 tube stock is available in different shapes and diameters. The outer diameters range from 6.53 mm to 127 mm, and larger sizes up to 24" NB are available upon request. The thickness of walls can be customized as it ranges from 0.020" to 0.220" (1 mm to 20 mm). For manufacturing, both seamless and welded options, such as ERW and EFW, can be used. For applications, these tubes are offered in round, square, rectangular, and hydraulic forms.

Strict quality checks are performed on each 254 SMO stainless steel tube prior to delivery. To ensure optimal performance in harsh conditions, tests include intergranular corrosion checks, PMI, flattening, flaring, and pressure. These tubes are packaged in wooden cases or bundles with the appropriate end caps to prevent any surface damage. Choose SMO 254 tubing built for strength, precision, and durability in every application.

| Specifications | ASTM A249 ASME SA249 / ASTM B269 ASME SB269 |

| Standard | ASTM, ASME and API |

| Dimensions | 3/4″ – 12″ |

| Schedule | SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH120, SCH140, SCH160, XXS |

| Type | Seamless / ERW / Welded / Fabricated |

| Form | Round, Hydraulic Etc |

| Length | Within 13500mm |

| End | Plain End, Beveled End, Treaded |

SMO 254 Seamless Tube

SMO 254 Welded Tube

SMO 254 ERW Tube

SMO 254 EFW Tube

SMO 254 Round Tube

SMO 254 Square Tube

SMO 254 Rectangular Tube

SMO 254 Polished Tube

Contact Preston Pipes and Alloys for best offer & competitive

quotation of SMO 254 Tubes

| Grade | Ni | C | Mo | Mn | Si | Fe | Cu | S | P | Cr |

| SMO 254 | 17.5 – 18.5 | 0.02 max | 6 – 6.5 | 1 max | 0.8 max | - | 0.5 – 1 | 0.01 max | 0.03 max | 19.5 – 20.5 |

| Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 8.0 g/cm3 | 1320-1390 ℃ | 300 | 650 | 35 % |

| STANDARD | UNS | WERKSTOFF NR. | AFNOR | EN | JIS | SIS | GOST |

| SMO 254 | S31254 | 1.4547 | Z1 CNDU 20.18.06Az | X1CrNiMoCuN20-18-7 | – | 2378 | – |