Contact

E-mail us

ASTM A240 Super Duplex S32750/S32760 Perforated Sheet, Chequered Plate Super Duplex Stainless Steel UNS S32750/S32760 Plates, Sheets and Coils Stockist and Supplier in Mumbai India.

Table of Content

Super Duplex Steel S32750 Sheet, Super Duplex Steel S32760 Sheet and their plate and coil variants are strong stainless steel products built for demanding environment. They have a duplex mix of austenite and ferrite giving high strength and excellent corrosion resistance. Super duplex UNS S32750 sheet suppliers offer materials with resistance to pitting and crevice corrosion, making them ideal for chloride-rich conditions. Super duplex 2507 sheets and plates, as well as super duplex UNS S32750 sheet stock offer outstanding mechanical performance. Super Duplex Steel S32760 Sheet and Super Duplex UNS S32760 Plate provide outstanding durability in aggressive environments. Super duplex 2507 coils and Super Duplex Steel S32760 Coil are easy to work with as they can cut and shaped for custom use. These alloys have balanced chemical composition and solid mechanical traits making them dependable for critical industries. Preston Pipes and Alloys supplies these products to meet international quality standards.

These steels bring several advantages. They have high tensile and yield strength, so they can bear heavy loads and pressure. They resist pitting, crevice corrosion, and stress cracking even in seawater or chemical rich areas. Good weldability makes them fit for complex structures. They also perform well in high-temperature operations. The ferritic-austenitic mix boosts both strength and corrosion resistance. Common uses include oil and gas platforms, subsea pipelines, and chemical processing tanks. They serve in marine engineering, desalination plants, and power plants, where equipment must handle corrosive fluids. The pulp and paper industry also uses them for equipment exposed to chemical process streams.

Super duplex 2507 sheets and super duplex 2507 plates come in widths from 1000mm to 3500mm and lengths up to 6000mm. Thickness ranges from 0.1mm to 100mm. Coils are available in varied widths and thicknesses, including slit and perforated types. Production involves steel making in electric arc furnaces, hot rolling, and, if needed, cold rolling for better finish and strength. Heat treatment and acid cleaning remove stress and surface oxides. Finishing steps can include polishing or cutting to exact sizes. Quality checks during each stage ensure consistent performance and compliance with ASTM A240 / ASME SA240 standards.

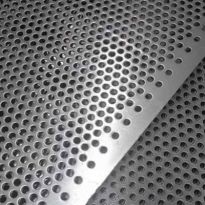

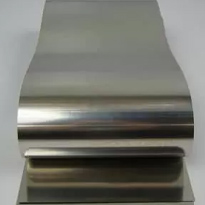

We supply forms like shim sheet, perforated sheet, B. Q. profile, foil, roll, strip, and chequered plate. Finishes range from hot rolled (HR) and cold rolled (CR) to 2B, BA, satin, and plastic-coated surfaces. Lengths include single random, double random, and cut lengths. Products are packed in boxes, crates, shrink wrap, carton boxes, wooden pallets, or wooden boxes, based on the item type. Each order is prepared for safe delivery to ensure the material reaches you in perfect condition.

| Specifications | ASTM A240 / ASME SA240 |

| Standards | ASTM, ASME and API |

| Thickness of Sheets (Cold Rolled) | Ranging from 0.3 mm to 6 mm |

| Thickness of Plates (Hot Rolled) | Ranging from 3.0 mm to 20 mm |

| Width | 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc |

| Thickness | 0.01~200mm |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc |

| Surface and Finish | 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sand blast, Brush, etching, etc |

| Form | Perforated Sheet, Chequered Plate, Flats, Shim Sheet, Foils, Blank (Circle), Ring (Flange) & Angle, Coils, Channel, Strip, etc. |

Super Duplex Steel S32750/S32760 Sheet

Super Duplex Steel S32750/S32760 Perforated Sheet

Super Duplex Steel S32750/S32760 Clad Plate

Cold Rolled Sheet

Hot Rolled Plate

Super Duplex Steel S32750/S32760 Coil

Super Duplex Steel S32750/S32760 Foil

Super Duplex Steel S32750/S32760 Shim Sheet

Get in touch with us for the best deal on Super Duplex Steel S32750/S32760 Sheet, Plate and Coil

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| S32750 | 0.030 max | 1.20 max | 0.80 max | 0.035 max | 0.020 max | 24.00 – 26.00 | 3.00 – 5.00 | 6.00 – 8.00 | 0.24 – 0.32 | 58.095 min |

| S32760 | 0.05 max | 1.00 max | 1.00 max | 0.030 max | 0.010 max | 24.00 – 26.00 | 3.00 – 4.00 | 6.00 – 8.00 | 0.20 – 0.30 | 57.61 min |

| Grades | Density (g/cm³) | Density (lb/in³) | Melting Point (°C) | Melting Point (°F) |

| S32750 / S32760 | 7.8 | 0.281 | 1350 | 2460 |

| STANDARD | WERKSTOFF NR. | UNS |

| Super Duplex 2507 | 1.4410 | S32750 / S32760 |