Contact

E-mail us

Hastelloy Alloy Plates, Hastelloy Metal, Hastelloy Plate Supplier, Hastelloy Plate Manufacturer, Hastelloy Plate In Mumbai, India, Hastelloy Plate For Sale

Table of Content

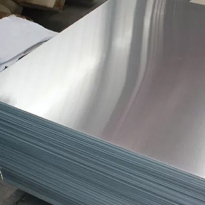

Hastelloy Alloy Plates are nickel-based alloys known for their superior resistance to corrosion, high strength, and stability in extreme environments, making them suitable for demanding industrial applications. Preston Pipes & Alloys is a trusted Hastelloy Plate Manufacturer and Supplier in Mumbai, India, delivering premium-quality Hastelloy Metal plates in grades like C22, C276, B2, and B3. As a trusted Hastelloy Plate Supplier, we ensure that our plates meet international standards, providing dependable, long-lasting, and varied performance across sectors.

A Hastelloy plate is a flat sheet made from a nickel-based alloy that delivers strong resistance to corrosion and high temperatures making it reliable in harsh industrial settings. With elements like molybdenum, chromium, and iron, the plate resists rust, pitting, and chemical attack, even in acidic or marine environments. It is frequently utilized in applications requiring durability and safety, such as chemical processing, power production, marine systems and pollution control equipment. Hastelloy plates retain their strength under heat and pressure while being weldable and fabricable, allowing them to be formed and joined without losing their protective properties.

The Hastelloy plate specification table lists details such as standards, thickness range, width, length, surface finish, and hardness. It helps buyers understand the dimensional options and technical standards available for different industrial uses.

| Specifications | ASTM / ASME SB575 |

| Size | 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm |

| Thickness | 0.1mm to 12 mm Thk |

| Form | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Strip, Flats, Blank (Circle), Ring (Flange) |

| Finish | Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) |

| Hardness | Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc. |

Order Hastelloy plates in your required thickness and size.

Hastelloy is durable, strong, and resistant to extreme environments. Its diverse qualities make it a dependable and long-lasting metal material.

- Corrosion Resistance: Hastelloy plates are known for their ability to withstand both oxidizing and reducing agents. They withstand extreme circumstances that many other alloys would fail in.

- High-Temperature Stability: These plates retain their strength and resist scaling even at high temperatures. This makes them suited for equipment that is subjected to heat and pressure.

- Fabricability: Hastelloy alloy plates can be formed and shaped without losing their strength or corrosion resistance. This allows easy adaptation to a wide range of designs and applications.

- Weldability: The alloy supports standard welding methods without cracking or losing properties. This helps in building secure joints for long-term use.

- Non-magnetic: Hastelloy plates are non-magnetic, which is useful in applications where magnetic interference must be avoided.

The chemical composition table for ASTM B575 Hastelloy plates shows the percentages of essential components including nickel, molybdenum, chromium, iron and others. This mixture provides outstanding corrosion resistance and great performance in harsh environments.

| Grade | C max | Cr | Mn max | Mo | Si max | S max | Co max | Ni min | Fe | P |

| C276 | 0.010 | 14.50 – 16.50 | 1.00 | 15.00 – 17.00 | 0.08 | 0.03 | 2.50 | 50.99 | 4.00 – 7.00 | 0.04 max |

| C22 | 0.010 | 20.00 – 22.50 | 0.50 | 12.50 – 14.50 | 0.08 | 0.02 | 2.50 | 50.015 | 2.00 – 6.00 | 0.02 max |

| B2 | 0.02 | 1.0 max | 1.00 | 26 – 30 | 0.1 | 0.03 | 1.0 | Balance | 2.0 max | 0.04 max |

| B3 | 0.01 | 1.5 max | 3.0 | 28.5 | 0.10 | 0.03 | 0.20 | 65.0 | 15 | 0.2 max |

The mechanical properties table provides details such as tensile strength, yield strength, and elongation of Hastelloy plates. These properties determine the material's strength, durability and their relevance for a variety of industrial uses.

| Grade | Density | Elongation | Tensile Strength | Melting Point | Yield Strength (0.2% Offset) |

| C22 | 1399 °C (2550 °F) | 45 % | 8.6 g/cm³ | Psi – 1,00,000 , MPa – 690 | Psi – 45,000 , MPa – 310 |

| C276 | 1370 °C (2500 °F) | 40 % | 8.89 g/cm³ | Psi – 1,15,000 , MPa – 790 | Psi – 52,000 , MPa – 355 |

| B2 | 1370 °C (2550 °F) | 40 % | 9.2 g/cm³ | Psi – 1,15,000 , MPa – 760 | Psi – 52,000 , MPa – 350 |

| B3 | 1370 °C (2550 °F) | 40 % | 9.2 g/cm³ | Psi – 1,15,000 , MPa – 760 | Psi – 52,000 , MPa – 350 |

| C4 | 1350 – 1400 °C | 55 % | 8.64 g/cm³ | 783 | 365 |

| Hybrid BC1 | 1343 – 1443 °C | 40 % | 8.83 g/cm³ | 725 | 310 |

| X | 1355 °C | 35 % | 8.22 g/cm³ | 655 MPa | 240 MPa |

Hastelloy plates come in several grades, each designed to handle harsh environments where corrosion is a major challenge. These plates are valued in industries like chemical processing, marine, and power generation because of their durability and strength. Below are the main types of Hastelloy plates with their key features.

Hastelloy C22 Plate

Hastelloy C22 plate offers excellent resistance to strong oxidizing and reducing chemicals. It performs well in wet chlorine, nitric acid, and mixed acid environments, making it a dependable choice for chemical plants and wastewater treatment equipment.

Hastelloy C276 Plate

Hastelloy C276 plate is one of the most widely used grades because of its ability to resist a wide range of corrosive conditions. It works effectively in both oxidizing and reducing atmospheres and stands up well to pitting and crevice corrosion.

Hastelloy B2 Plate

Hastelloy B2 plate is highly resistant to hydrochloric acid at all concentrations and temperatures. It also offers good protection against pure sulfuric and phosphoric acids, which makes it suitable for acid production and chemical storage.

Hastelloy B3 Plate

Hastelloy B3 plates are better than B2 by offering better thermal stability and handling a wider range of acidic conditions. It provides strong resistance against hydrochloric acid, and other aggressive media while maintaining high mechanical strength

The sizing chart provides conventional dimensions for Hastelloy plates, including as common thicknesses, widths (in millimeters) and lengths (in meters or millimeters). This helps engineers and buyers quickly reference available sizes for project planning and specification

| Hastelloy steel sheet size (milimeter) | Hastelloy alloy plate size (inches) |

| 3.4 | 0.134 |

| 3.18 | 0.125 |

| 4.75 | 0.187 |

| 3.96 | 0.156 |

| 7.92 | 0.312 |

| 6.35 | 0.25 |

| 12.7 | 0.5 |

| 9.53 | 0.375 |

| 15.9 | 0.6 |

| 22.2 | 0.875 |

| 19.1 | 0.75 |

| 25.4 | 1 |

| 76.2 | 3 |

| 31.8 | 1.25 |

| 28.6 | 1.125 |

| 38.1 | 1.5 |

| 50.8 | 2 |

| 44.5 | 1.75 |

| 63.5 | 2.5 |

The thickness tolerance table compares Hastelloy plates by gauge and size, including dimensions in millimeters and inches. This allows users to select the proper plate thickness based on their project requirements and international standards.

| Thickness -l. | Thickness in inch |

| +/- .003″ | Over .016 – .026, incl. |

| +/- .004″ | Over .026 – .040, incl. |

| +/- .005″ | Over .040 – .058, incl. |

| +/- .006″ | Over .058 – .072, incl. |

| +/- .007″ | Over .072 – .083, incl. |

| +/- .008″ | Over .083 – .098, incl. |

| +/- .009″ | Over .098 – .114, incl. |

| +/- .010″ | Over .114 – .130, incl. |

| +/- .012″ | Over .130 – .145, incl. |

| +/- .014″ | Over .145 – .1875, excl. |

| + .045″, – 0″ | .1875 – .375, excl. |

| + .055″, – 0″ | .375 – .75, excl. |

| + .060″, – 0″ | .75 – 1, excl. |

Hastelloy plates come in a variety of grades and types, all made to withstand certain corrosive conditions and industrial demands.

Hastelloy Sheet

Hastelloy Coil

Hastelloy Strip

Hastelloy Foil

Hastelloy Shim Stock

Hastelloy Perforated Sheet

Hastelloy Clad Plate

Hastelloy Cold Rolled Plate

Hastelloy Hot Rolled Plate

FAQ

- Superior resistance to oxidizing and reducing agents

- Excellent performance in high-temperature and high-stress environments

- Exceptional durability in severely corrosive environments, such as seawater and chemical media.

- High strength and long service life, reducing maintenance and replacement costs