Contact

E-mail us

Stainless Steel Plates Suppliers, SS Plate Manufacturer, Stainless Steel Plate Manufacturers In India, Stainless Steel Sheet Manufacturers

Table of Content

A stainless steel plate is a strong sheet designed of corrosion-resistant steel that provides strength, hardness and a smooth surface. Preston Pipes & Alloys, a trusted stainless steel plate supplier in India, provides high-quality stainless steel metal plates in various grades, specifications, and finishes. Our plates combine toughness, temperature resistance and excellent surface appeal. It is designed for lasting performance and maintains strength and finish under stress and harsh conditions. With exact dimensions and dependable manufacture, our stainless steel plates offer consistent quality, making them an ideal choice for a variety of industrial applications.

A stainless steel plate is a flat, solid sheet made from corrosion-resistant steel, designed for strength and durability. It combines hardness and resilience with a smooth, polished surface, ensuring long-term performance under stress and harsh circumstances. Stainless steel plates resist rust, wear, and chemical damage, maintaining their quality over time. They are made using a variety of manufacturing techniques, such as forging, hot rolling, and cold rolling, which contribute to their excellent mechanical qualities, consistent surface and accurate thickness. SS plates are ideal for structural, decorative, and industrial applications because they are simple to shape, cut and weld. With consistent dimensions and high-quality finishes these plates provide reliability and efficiency across a wide range of applications.

The specification table for Stainless Steel 304 Sheets provides detailed information on dimensions, thicknesses, weights, and tolerances. This ensures that your projects are carefully selected and of the highest quality.

| Specifications | ASTM A240 / ASME SA240 |

| Thickness | 4 mm – 100 mm |

| Width | 1000 mm, 1219 mm, 1500 mm, 1800 mm, 2000 mm, 2500 mm, 3000 mm, 3500 mm, etc. |

| Length | 2000 mm, 2440 mm, 3000 mm, 5800 mm, 6000 mm, etc. |

| Surface | 2B, 2D, BA, No.1, No.4, No.8, 8K, Mirror, Checkered, Embossed, Hair Line, Sand Blast, Brush, Etching, etc. |

| Finish | Hot Rolled Plate (HR), Cold Rolled Sheet (CR), 2B, 2D, BA, No.8, Satin (with Plastic Coating) |

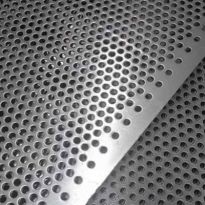

| Form | Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange), etc. |

Buy Stainless Steel Plates for sale at low prices in various sizes

Stainless steel is durable, strong, and resistant to extreme environments. Its diverse qualities make it a dependable and long-lasting metal material.

- Corrosion Resistance: Stainless steel resists rust, oxidation, and chemical damage. It maintains its integrity and surface quality over time.

- High Tensile Strength: It withstands high pulling forces without breaking. This ensures strength and stability under heavy loads.

- Good Yield Strength: The metal bends less under stress, keeping its shape and structure over time.

- High hardness: Stainless steel resists scratches, dents, and surface wear. Its durability keeps it strong and long-lasting.

- Fatigue Resistance: It tolerates repeated stress without cracking or weakening. This ensures reliability in demanding conditions.

- Attractive Surface and Finish: The smooth, polished finish remains bright and clean. Stainless steel keeps a professional and appealing look.

- Temperature Resistance: It maintains strength and stability across a wide range of temperatures, from extreme heat to extreme cold.

- Good Formability and Weldability: Stainless steel bends, shapes, and welds easily without compromising strength. It allows precise fabrication and shaping.

- Additional Benefits: The metal requires little maintenance and retains its quality over time. Its combination of strength, and corrosion resistance assures long-lasting dependability.

Stainless steel plates come in a variety of grades, each designed to offer specific strength, corrosion resistance, and heat tolerance. Picking the right grade ensures long-lasting performance in industrial, marine, or construction applications.

Stainless Steel 304 Plate

Grade 304 is the most popular type of stainless steel plate. It provides high corrosion resistance, formability and strength. It works well in kitchen equipment, storage tanks, and general construction.

Stainless Steel 304L Plate

304L is a low-carbon variant of 304. It resists corrosion after welding and maintains a smooth, polished finish. Ideal for chemical tanks, piping, and welded structures.

Stainless Steel 309 Plate

309 plates perform well at high temperatures. They resist oxidation and scaling, making them suitable for furnace parts, boiler components, and heat-resistant equipment.

Stainless Steel 310 Plate

310 grade is designed for high heat situations. It retains structural integrity at high temperatures and is commonly used in kilns, ovens, and heat exchangers.

Stainless Steel 316 Plate

316 plates are extremely resistant to corrosion from saltwater and chemicals. They are ideal for marine environments, chemical processing units, and medical equipment.

Stainless Steel 316L Plate

316L is a low-carbon version of 316. It prevents carbide precipitation during welding, keeping corrosion resistance intact. Commonly used in tanks, pipelines, and marine equipment.

Stainless Steel 317 Plate

310 grade is designed for high heat situations. It retains structural integrity at high temperatures and is commonly used in kilns, ovens and heat exchangers.

Stainless Steel 317L Plate

Despite having less carbon, 317L offers the same corrosion resistance as 317. It is perfect for pipes, pressure vessels, and welded chemical tanks.

Stainless Steel 321 Plate

321 plates can withstand high temperatures and stress corrosion. Titanium stabilization decreases carbide formation, making it suitable for aerospace, exhaust systems, and high-temperature applications.

Stainless Steel 347 Plate

The 347 grade provides good resistance to intergranular corrosion. Niobium stabilization enhances the durability of welded structures, heat exchangers, and high-temperature equipment.

Stainless Steel 446 Plate

At high temperatures, 446 is especially resistant to oxidation and scaling. It is frequently used in industrial ovens, heat exchangers and furnace components.

Stainless Steel 904L Plate

904L provides superior corrosion resistance against acids, chlorides, and aggressive chemicals. It is suitable for chemical plants, marine equipment, and highly corrosive environments.

Stainless steel plates come in a variety of conventional and customized sizes. The table contains detailed dimensions, thicknesses and widths.

| Sizes (mm) | Kg/Plate (304/316L & 3CR12) Austenitic and Ferritic |

| 2500 x 1250 x 4.5 | 115.31 |

| 3000 x 1500 x 4.5 | 166.05 |

| 6000 x 1500 x 4.5 | 332.10 |

| 6000 x 2000 x 4.5 | 442.80 |

| 2500 x 1250 x 6 | 153.75 |

| 3000 x 1500 x 6 | 221.40 |

| 6000 x 1500 x 6 | 442.80 |

| 6000 x 2000 x 6 | 590.40 |

| 2500 x 1250 x 8 | 205.00 |

| 3000 x 1500 x 8 | 295.20 |

| 6000 x 1500 x 8 | 590.40 |

| 6000 x 2000 x 8 | 787.20 |

| 2500 x 1250 x 10 | 256.25 |

| 3000 x 1500 x 10 | 369.00 |

| 6000 x 1500 x 10 | 738.00 |

| 6000 x 2000 x 10 | 984.00 |

| 2500 x 1250 x 12 | 307.50 |

| 3000 x 1500 x 12 | 442.80 |

| 6000 x 1500 x 12 | 885.60 |

| 6000 x 2000 x 12 | 1180.80 |

| 2500 x 1250 x 16 | 410.00 |

| 3000 x 1500 x 16 | 590.40 |

| 2500 x 1250 x 20 | 512.50 |

| 3000 x 1500 x 20 | 738.00 |

| 2500 x 1250 x 25 | 640.63 |

| 3000 x 1500 x 25 | 922.50 |

| 2500 x 1250 x 30 | 768.75 |

| 3000 x 1500 x 30 | 1107.00 |

| 2500 x 1250 x 40 | 1025.00 |

| 3000 x 1500 x 40 | 1476.00 |

| 2500 x 1250 x 50 | 1281.25 |

| 3000 x 1500 x 50 | 1845.00 |

Stainless Steel Sheet

Stainless Steel Coil

Stainless Steel Strip

Stainless Steel Foil

Stainless Steel Shim Stock

Stainless Steel Perforated Sheet

Stainless Steel Chequered Plate

Stainless Steel Cold Rolled Plate

Stainless Steel Hot Rolled Plate

Stainless Steel Decorative Sheet

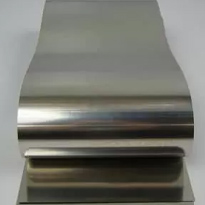

Stainless steel plates come in various finishes to match appearance and functionality needs. Each finish offers a different texture, shine, and corrosion resistance.

| Surface Finish | Description / Typical Use |

| No.1 | Hot-rolled, annealed and pickled. Rough, matte surface used where finish is not critical. |

| 2D | Cold-rolled, annealed and pickled; smooth, dull gray finish commonly used for forming and general fabrication. |

| 2B | Cold-rolled, annealed, pickled and lightly polished to a smooth, bright finish — most common general-purpose finish. |

| BA (Bright Annealed) | Bright annealed in a controlled atmosphere producing a reflective surface, slightly less reflective than No.8. |

| No.4 (Brushed / Satin) | Uniform fine polish using ~150–180 grit; produces a brushed satin appearance used in appliances and architectural panels. |

| Hairline | Long, continuous directional polish with very fine grain — decorative panels, elevator interiors, trim. |

| No.8 / 8K (Mirror) | Highly polished, mirror-like surface for decorative applications and reflective surfaces. |

| Bead / Sand Blasted | Matte, non-reflective surface created by abrasive or bead blasting; reduces glare and hides small imperfections. |

| Etched | Acid or chemical etching to create patterns, textures or logos for decorative applications. |

| Embossed / Checkered (Tread) | Raised patterns such as 5-bar tread for slip-resistance and decorative purposes; commonly used for flooring and plates. |

Stainless steel plates offer strength, durability, and corrosion resistance. They fit seamlessly into many industrial uses.

-

Construction and ArchitectureStainless steel plates provide lasting support in buildings and bridges. Structures remain strong and safe because of their resistance to rust. They are used by architects for decorative features, stairways, and facades.

-

Chemical and Petrochemical IndustryIn chemical plants, stainless steel plates resist acids, alkalis, and harsh chemicals. They line tanks, pipes, and reactors, protecting equipment from corrosion.

-

Oil and Gas IndustryOil rigs and refineries face extreme conditions. These plates handle pressure, saltwater, and temperature changes while keeping pipelines and storage tanks durable.

-

Automotive and TransportationCar makers use SS plates for exhaust systems, chassis parts, and fuel tanks. They ensure vehicles stay strong and resist rust over time.

-

Marine IndustryIn ships, docks and offshore platforms, stainless steel plates survive longer because saltwater corrodes metals more quickly. They ensure the safety of equipment and boats.

-

Energy and Power GenerationPower plants rely on stainless steel plates for boilers, turbines, and heat exchangers. Their heat resistance and durability allow for effective energy production.